RS485, Modbus RTU & Model Selection Guide

소개

In modern industrial automation, accurate and stable 거리 측정 is essential for closed-loop control, positioning, safety interlocks, and process optimization. Among the available industrial communication options, Modbus RTU over RS485 remains one of the most widely adopted standards due to its simplicity, robustness, and compatibility with PLCs, HMIs, and SCADA systems.

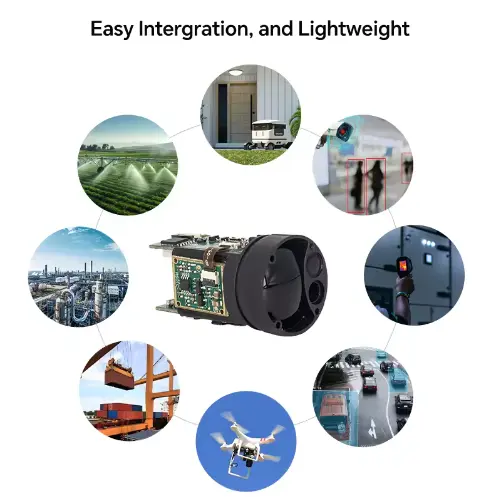

A Modbus laser 거리 센서 combines non-contact 광학 measurement with industrial-grade communication, making it ideal for harsh environments where ultrasonic or mechanical sensors may struggle. This guide explains how industrial Modbus distance sensors work, why RS485 is preferred, and—most importantly—how to select the right model based on real industrial requirements.

Why Use a Modbus Laser Distance Sensor in Industrial Environments

Industrial automation places strict demands on sensors. A consumer-grade distance sensor may perform well in the lab but fail in real-world installations due to electrical noise, temperature variation, or mechanical vibration.

An industrial Modbus distance sensor is designed specifically to address these challenges:

- High noise immunity using differential RS485 signaling

- Long communication distance, typically up to 1000 m with proper cabling

- Multi-drop networking, allowing multiple sensors on a single bus

- Seamless PLC integration with Siemens, Mitsubishi, Omron, Beckhoff, and others

- Stable long-term operation for 24/7 industrial systems

Laser-based distance measurement further adds the benefit of non-contact sensing, making it suitable for moving objects, high-temperature surfaces, and hard-to-reach targets.

Modbus RTU Communication via RS485 Explained

Why RS485 Is Preferred in Industrial Distance Measurement

RS485 is the physical layer most commonly used with Modbus RTU in industrial environments. Compared with TTL or RS232, RS485 offers:

- Differential signaling for strong EMI resistance

- Support for long cable runs

- Multi-device bus topology

- High reliability in electrically noisy environments

For 레이저 거리 sensors installed near motors, inverters, or welding equipment, RS485 is often the only practical option.

Typical Modbus RTU Parameters

Most Modbus 레이저 거리 센서 share similar communication settings:

| 매개변수 | Typical Value |

|---|

| Protocol | Modbus RTU |

| 인터페이스 | RS485 |

| Baud Rate | 9600 / 19200 / 115200 |

| Data Bits | 8 |

| Parity | None / Even |

| Stop Bits | 1 |

| Device Address | 1–247 |

Distance values are usually stored in holding registers and can be read cyclically by the PLC for real-time control or monitoring.

Industrial Stability: What Really Matters

When selecting a Modbus 레이저 거리 센서, accuracy alone is not enough. Industrial stability depends on several factors:

- Temperature range: Industrial sites may experience wide temperature swings

- Protection level: IP54–IP67 housings protect against dust and moisture

- Mechanical robustness: Resistance to vibration and shock

- Electrical reliability: Stable operation under fluctuating power conditions

- EMC performance: Compliance with industrial electromagnetic standards

Sensors designed with metal housings, industrial connectors, and tested EMC characteristics provide far better long-term reliability than bare modules.

Modbus Laser Distance Sensor Model Selection Table

The following table summarizes real 산업용 레이저 거리 센서 models that support RS485 and Modbus RTU, helping engineers quickly compare options based on range, accuracy, and environmental requirements.

| Model Series | 측정 범위 | 정확성 | 출력 인터페이스 | Protection | 일반적인 애플리케이션 |

| Compact Phase Module (Red Laser) | 0.03–60 / 80 / 100 m | ±(1 mm + D×10⁻⁴) | RS485 Modbus RTU | Module-level | PLC automation, positioning systems |

| Ultra-Compact Phase Module | 0.03–60 / 80 / 100 m | ±(1 mm + D×10⁻⁴) | RS485 Modbus RTU | Module-level | Embedded industrial devices |

| Standard Phase Module | 0.03–10 / 20 / 40 m | ±(3 mm + D×10⁻⁴) | RS485 Modbus RTU | Module-level | Conveyor measurement, machine tools |

| Long-Range Phase Module | 0.03–100 / 150 / 200 m | ±(3 mm + D×10⁻⁴) | RS485 Modbus RTU | Module-level | Industrial positioning, automation |

| Green Laser Phase Module | 0.03–100 / 150 / 200 m | ±(3 mm + D×10⁻⁴) | RS485 Modbus RTU | Module-level | Outdoor & high-ambient-light use |

| Industrial Housing (IP54) | 0.03–100 / 150 / 200 m | ±(3 mm + D×10⁻⁴) | RS485 Modbus RTU | IP54 | Factory automation, fixed installations |

| Industrial Housing (IP67) | 0.03–100 / 150 / 200 m | ±(3 mm + D×10⁻⁴) | RS485 Modbus RTU | IP67 | Harsh or outdoor industrial environments |

| High-Frequency Distance Module | 0.2–25 m | ±(3 mm + D×10⁻⁴) | RS485 Modbus RTU | IP54 / IP67 | High-speed control, dynamic targets |

팁: For PLC-based systems, choose sensors with IP-rated housings when installed directly on production lines. Module-level sensors are better suited for OEM integration inside protected enclosures.

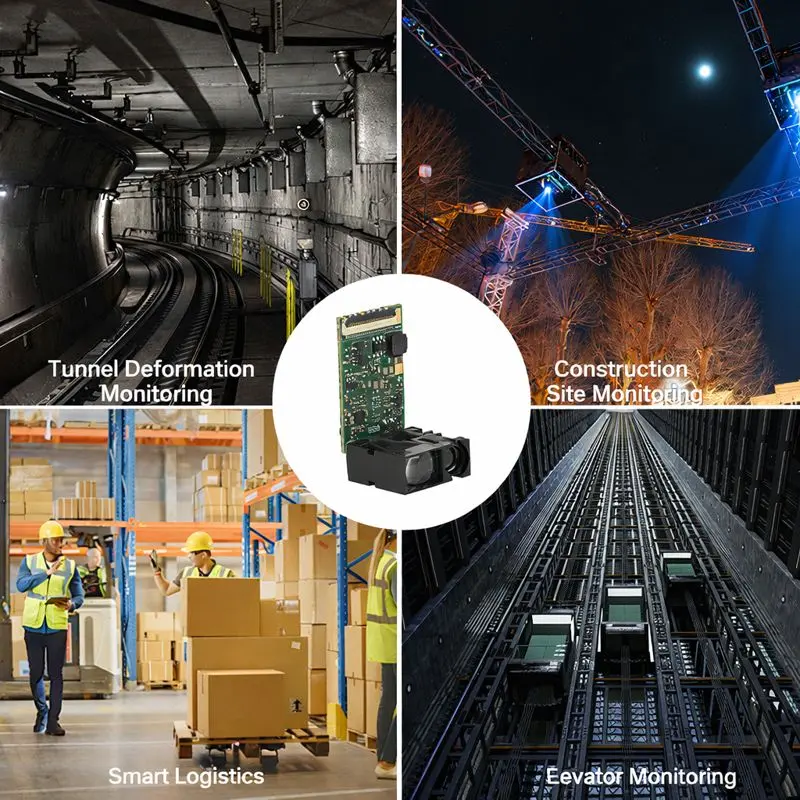

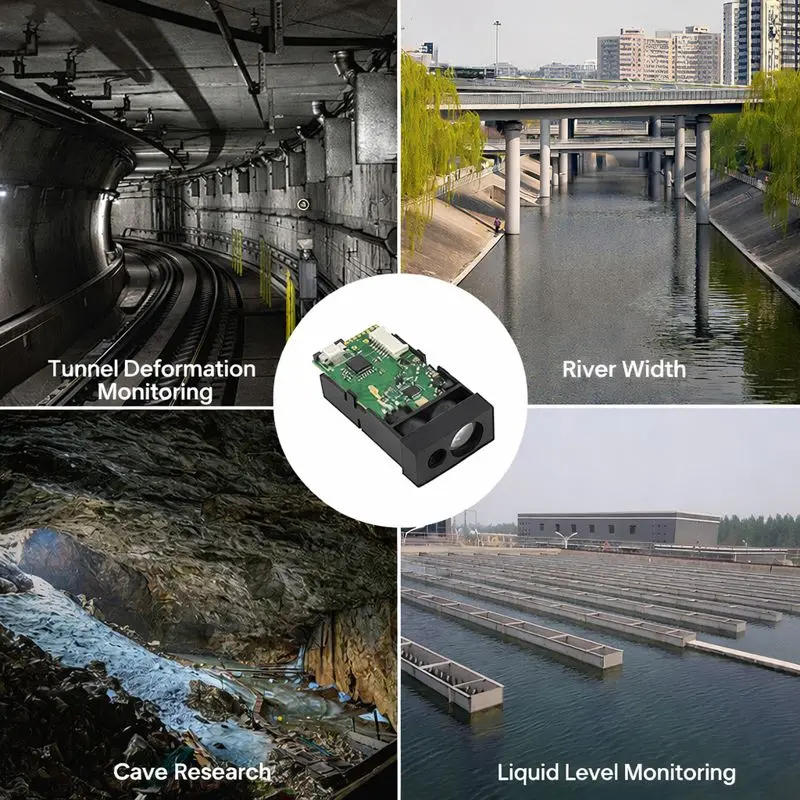

Typical Industrial Applications

Modbus laser distance sensors are widely used across industrial sectors:

- PLC-based distance control in automated machinery

- Conveyor belt positioning and 높이 측정

- AGV and mobile robot navigation

- Warehouse automation and pallet 탐지

- Crane positioning and collision avoidance

- Industrial level measurement for solids or liquids

Their non-contact nature allows reliable operation where mechanical wear or contamination would otherwise cause failures.

Integrating a Modbus Laser Distance Sensor with PLC Systems

Most PLC integrations follow a similar workflow:

- Connect the sensor to the RS485 bus

- Set device address and baud rate

- Import Modbus register definitions

- Read distance registers cyclically

- Apply scaling and filtering in the PLC

Modbus RTU ensures compatibility with major PLC platforms without custom drivers or proprietary protocols.

How to Choose the Right Model

When selecting an industrial Modbus distance sensor, consider:

- Required measurement range and accuracy

- Environmental conditions (dust, moisture, temperature)

- Installation space and housing requirements

- Update rate and response time

- Integration method with existing PLC or control system

Choosing the correct model at the design stage significantly reduces commissioning time and long-term maintenance costs.

결론

A Modbus laser distance sensor with RS485 communication is a proven solution for industrial distance measurement. By combining optical precision with robust industrial communication, these sensors deliver reliable performance in demanding automation environments.

Using the model selection table above, engineers and system integrators can quickly identify the most suitable industrial Modbus distance sensor for their application.

If you need assistance with model selection, Modbus register mapping, or OEM customization, our engineering team is ready to support your project.

FAQ – Modbus Laser Distance Sensors for Industrial Automation

-

What is a Modbus laser distance sensor?

A Modbus laser distance sensor is a non-contact distance measurement device that transmits measurement data using the Modbus RTU protocol, typically over an RS485 interface, allowing direct integration with PLCs and industrial control systems.

-

Why is RS485 commonly used with Modbus laser distance sensors?

RS485 is used because it provides differential signaling with strong noise immunity, supports long-distance communication up to hundreds of meters, and allows multiple Modbus devices to share the same communication bus in industrial environments.

-

What is the difference between Modbus RTU and Modbus TCP for distance sensors?

Modbus RTU is a serial communication protocol commonly used with RS485 for industrial sensors, while Modbus TCP runs over Ethernet. Modbus RTU is preferred for laser distance sensors in harsh environments due to its simplicity, stability, and lower hardware requirements.

-

How accurate are industrial Modbus laser distance sensors?

Industrial Modbus laser distance sensors typically offer millimeter-level accuracy, commonly ±1 mm to ±3 mm depending on the model, measurement range, and target surface characteristics.

-

Can Modbus laser distance sensors be connected directly to PLCs?

Yes, Modbus laser distance sensors can be connected directly to PLCs via RS485. Most PLCs natively support Modbus RTU and can read distance values from holding registers without additional gateways.

-

How many Modbus laser distance sensors can be connected on one RS485 bus?

Up to 247 Modbus laser distance sensors can theoretically be connected on a single RS485 bus, as each device must have a unique Modbus address, although practical limits depend on cable length and system design.

-

What baud rate is recommended for Modbus laser distance sensors?

Common baud rates include 9600, 19200, and 115200 bps. For most industrial distance measurement applications, 19200 or 115200 bps offers a good balance between stability and response speed.

-

Are Modbus laser distance sensors suitable for harsh industrial environments?

Yes, industrial Modbus laser distance sensors are designed for harsh environments and are available with IP54 to IP67 protection, metal housings, and stable performance across wide temperature ranges.

-

What industries commonly use Modbus laser distance sensors?

Modbus laser distance sensors are widely used in industrial automation, material handling, AGV navigation, conveyor positioning, warehouse systems, crane control, and industrial level measurement applications.

-

How do I choose the right Modbus laser distance sensor model?

To choose the right model, consider the required measurement range, accuracy, environmental conditions, communication interface (RS485 Modbus RTU), update rate, and whether an IP-rated housing is needed for the installation environment.

-

Can Modbus laser distance sensors be customized for OEM projects?

Yes, many Modbus laser distance sensors support OEM customization, including communication parameters, housing design, protection level, and Modbus register mapping to match specific industrial requirements.

-

Are Modbus laser distance sensors better than ultrasonic sensors?

Modbus laser distance sensors generally provide higher accuracy, faster response, and better performance on small or distant targets compared to ultrasonic sensors, especially in industrial automation applications.