ToF Laser-Sensoren (Flugzeitsensor) revolutionieren Branchen, in denen Genauigkeit gefragt ist, berührungslose Messung über unterschiedliche Entfernungen. Dank ihrer Fähigkeit, schnelle und präzise Messwerte zu liefern, wird die ToF-Technologie zunehmend in Bereichen eingesetzt, die von der industriellen Automatisierung und Robotik bis zur Umweltüberwachung und Unterhaltungselektronik reichen. In diesem Blog-Beitrag werden wir die Vorteile von ToF-Lasersensoren erkunden, wie sie funktionieren und warum sie in den folgenden Bereichen als bahnbrechende Neuerung gelten Abstandsmessung Technologie.

Was sind ToF-Lasersensoren?

ToF-Laser-Sensoren arbeiten, indem sie die Zeit messen, die ein Laserpuls braucht, um zu einem Ziel zu gelangen und wieder zurückzukehren. Diese Zeitdifferenz wird dann in eine Entfernungsmessung umgerechnet, wobei die Lichtgeschwindigkeit als Konstante verwendet wird. ToF-Sensoren sind besonders nützlich für Anwendungen, bei denen präzise Entfernungsmessungen entscheidend sind, wie z. B. bei autonomen Fahrzeugen, Industrierobotern und 3D-Scannern.

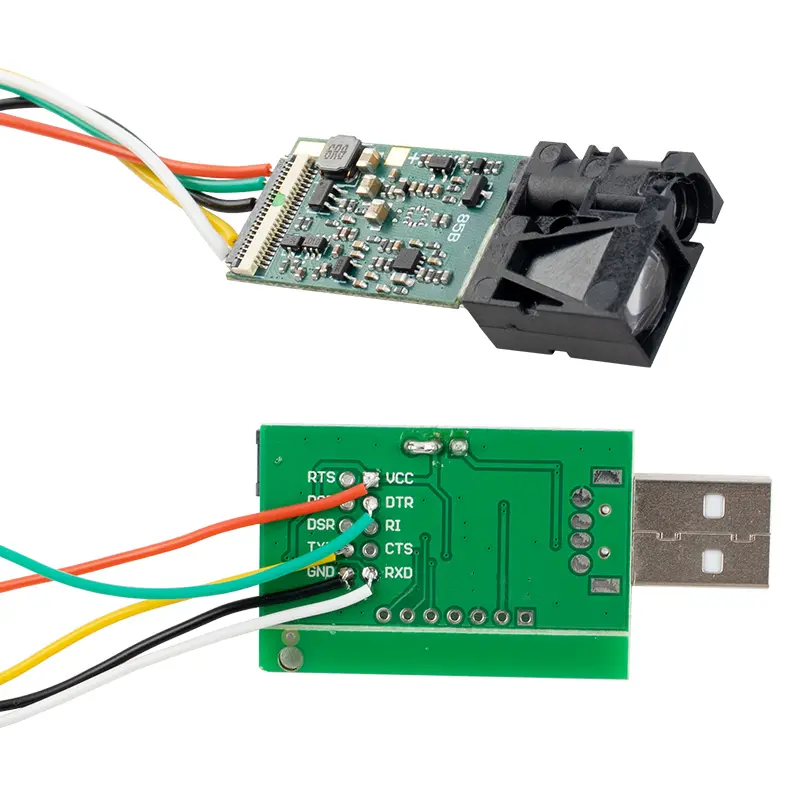

ToF-Sensoren bestehen in der Regel aus drei Hauptkomponenten:

Laser-Emitter - Sendet einen Lichtimpuls in Richtung des Ziels.

Empfänger - Erfasst das vom Ziel reflektierte Licht.

Signalprozessor - Berechnet die Entfernung anhand der Zeit, die für die Rückkehr des Pulses benötigt wird.

Mit dieser Methode können ToF-Sensoren Entfernungen mit unglaublicher Genauigkeit und Geschwindigkeit messen, selbst unter schwierigen Bedingungen, bei denen andere Messtechnologien Schwierigkeiten haben könnten.

Wie funktionieren ToF-Lasersensoren?

Der Kern der ToF-Technologie basiert auf der Berechnung der Zeit, die ein Laserpuls benötigt, um zu einem Objekt zu gelangen und wieder zurückzukehren. Im Folgenden wird die Funktionsweise von ToF-Sensoren Schritt für Schritt erläutert:

Emission: Ein Laserlichtpuls wird in Richtung des Ziels gesendet.

Reflexion: Der Impuls wandert und wird von der Oberfläche des Ziels reflektiert.

Rezeption: Der reflektierte Impuls wird von einem Fotodetektor oder Sensor empfangen.

Zeitberechnung: Der Sensor misst die Zeit, die das Licht für den Weg zum Ziel und zurück benötigt.

Berechnung der Entfernung: Anhand der bekannten Lichtgeschwindigkeit berechnet der Sensor die genaue Entfernung vom Sensor zum Objekt.

Dieser Messprozess ist unglaublich schnell, denn ToF-Sensoren liefern in der Regel Echtzeitdaten mit hoher Frequenz (bis zu Tausende von Messungen pro Sekunde).

Vorteile von ToF-Lasersensoren

1. Hohe Genauigkeit und Präzision

ToF laser sensors are known for their exceptional accuracy. Thanks to the precise measurement of the time of flight, these sensors can measure distances with sub-millimeter precision, even at long ranges. This is a significant advantage in applications like industrial automation and 3D scanning, where accuracy is paramount.

2. Großer Messbereich

Eines der herausragenden Merkmale von ToF-Sensoren ist ihre Fähigkeit, Entfernungen über große Bereiche - oft bis zu mehreren hundert Metern oder mehr - zu messen, ohne an Genauigkeit zu verlieren. Dies macht sie ideal für Anwendungen wie z. B. im Freien Vermessung, Konstruktionund Entfernungsmessungen mit großer Reichweite in autonomen Fahrzeugen.

3. Hochgeschwindigkeits- und Echtzeitdaten

ToF-Sensoren sind in der Lage, Messungen in Echtzeit zu liefern, wodurch sie sich für Hochgeschwindigkeitsanwendungen wie Robotik und autonome Systeme eignen. Dank der schnellen Datenerfassung ermöglichen diese Sensoren dynamische Entscheidungen und eine präzise Steuerung.

4. Berührungslose Messung

ToF-Sensoren messen die Entfernung ohne physischen Kontakt mit dem Ziel und eignen sich daher perfekt für Anwendungen in sensiblen oder gefährlichen Umgebungen. Diese berührungslose Funktion eliminiert das Risiko der Abnutzung des Sensors, reduziert die Wartungskosten und verbessert die Sicherheit in industriellen und Outdoor-Anwendungen.

5. Vielseitigkeit für verschiedene Anwendungen

ToF-Lasersensoren können in einer Vielzahl von Branchen und Anwendungen eingesetzt werden, z. B:

- Autonome Fahrzeuge: Für Hindernisse Erkennung und Navigation.

- Industrielle Automatisierung: Zur präzisen Positionsbestimmung und Entfernungsmessung.

- 3D-Scannen: Erstellung präziser 3D-Modelle für digital Kartierung.

- Unterhaltungselektronik: In Anwendungen wie Gesichtserkennung und Augmented Reality.

- Umweltüberwachung: Um Entfernungen zu messen und atmosphärische Veränderungen festzustellen.

ToF-Lasersensoren im Vergleich zu anderen Lasersensoren

ToF-Lasersensoren bieten zwar viele Vorteile, aber es ist wichtig, sie mit anderen Lasersensortypen zu vergleichen, um ihre Vorzüge voll auszuschöpfen. Werfen wir einen Blick darauf, wie sich ToF-Sensoren im Vergleich zu anderen gängigen Typen von Laserdistanz Sensoren:

1. ToF vs. Triangulationssensoren

- Triangulationssensoren verwenden den Reflexionswinkel zur Berechnung der Entfernung. Während sie für Messungen im Nahbereich genau sind, haben sie bei größeren Entfernungen oder stark reflektierenden Oberflächen Probleme. Im Gegensatz dazu können ToF-Sensoren viel größere Entfernungen mit höherer Genauigkeit messen, insbesondere in komplexen Umgebungen.

2. ToF vs. Phasenverschiebungssensoren

- Phasenverschiebungssensoren messen die Phasendifferenz zwischen dem gesendeten und dem empfangenen Signal. Während sie bei kurzen Entfernungen präziser sein können, bieten ToF-Sensoren eine bessere Leistung bei größeren Entfernungen und schnellere Messzeiten, wodurch sie sich besser für Hochgeschwindigkeitsanwendungen eignen.

Anwendungen von ToF-Lasersensoren

Die Anwendungen von ToF-Sensoren Die Möglichkeiten der ToF-Lasersensoren sind vielfältig, und mit der fortschreitenden Verbesserung der Technologie steigt auch ihr Potenzial in allen Branchen. Einige gängige Bereiche, in denen ToF-Lasersensoren zum Einsatz kommen, sind:

- Robotik und Automatisierung: Für präzise Navigation und Hinderniserkennung in Robotern und autonomen Systemen.

- Bauwesen: Wird für Abstandsmessungen in Gebäuden, die Erstellung von 3D-Modellen von Bauwerken und zur Gewährleistung der Präzision bei Bauprojekten verwendet.

- Landwirtschaft: Kartierung von Feldern und Überwachung von Wachstum und Gesundheit der Pflanzen durch berührungslose Messung.

- Unterhaltungselektronik: Für die Gesichtserkennung in Smartphones und Augmented-Reality-Geräten.

- Vermessung und Kartierung: Zur Erfassung topografischer Daten und zur Erstellung digitaler Höhenmodelle.

FAQs über ToF-Lasersensoren

Q1: Wie groß ist die Reichweite von ToF-Lasersensoren?

Die Reichweite von ToF-Lasersensoren variiert je nach Modell und Anwendung. Im Allgemeinen können sie Entfernungen von wenigen Zentimetern bis zu mehreren hundert Metern messen.

F2: Wie genau sind ToF-Lasersensoren?

ToF-Lasersensoren bieten eine hohe Genauigkeit, oft im Sub-Millimeter-Bereich, auch bei großen Entfernungen. Dies macht sie ideal für Anwendungen, die präzise Messungen erfordern.

F3: Werden ToF-Lasersensoren durch das Umgebungslicht beeinflusst?

ToF-Lasersensoren sind so konzipiert, dass sie gegen Störungen durch Umgebungslicht resistent sind. Dennoch können extrem helle Bedingungen die Sensorleistung beeinträchtigen. Moderne Modelle enthalten oft Filter, um dieses Problem zu entschärfen.

F4: In welchen Branchen werden ToF-Lasersensoren eingesetzt?

ToF-Sensoren werden in einer Vielzahl von Branchen eingesetzt, darunter Robotik, autonome Fahrzeuge, Bauwesen, Landwirtschaft, Unterhaltungselektronik und Umweltüberwachung.

F5: Wie schnell können ToF-Lasersensoren Messungen durchführen?

ToF-Sensoren können Messungen in Echtzeit durchführen, wobei einige Modelle in der Lage sind, Tausende von Messungen pro Sekunde vorzunehmen. Diese Geschwindigkeit ist entscheidend für dynamische Anwendungen wie Robotik und autonome Navigation

F6: Sind ToF-Sensoren leicht in bestehende Systeme zu integrieren?

Ja, ToF-Sensoren sind aufgrund ihrer kompakten Größe und einfachen Schnittstelle im Allgemeinen leicht in bestehende Systeme zu integrieren. Viele Modelle bieten standardisierte Kommunikationsprotokolle, wie I2C oder UARTfür eine nahtlose Integration.

Flugzeit (ToF)-Lasersensoren bieten eine Vielzahl von Vorteilen, darunter hohe Genauigkeit, große Reichweite und hohe Messgeschwindigkeit, was sie zur idealen Wahl für verschiedene Branchen und Anwendungen macht. Ob in der industriellen Automatisierung, bei autonomen Fahrzeugen oder beim 3D-Scannen - ToF-Sensoren prägen die Zukunft der Abstandsmesstechnik. Mit den laufenden Fortschritten werden die Anwendungsmöglichkeiten für ToF-Lasersensoren nur noch weiter wachsen.

Wenn man die Vorteile und Möglichkeiten von ToF-Lasersensoren kennt, kann die Industrie diese Technologie nutzen, um die Präzision, Effizienz und Sicherheit ihrer Abläufe zu verbessern.

https://meskernel.net/how-does-tof-sensor-work/