Industrial laser sensor vs Arduino-based solutions are often evaluated during early development, but the right choice becomes critical when moving toward stable, real-world deployment.

The comparison between an industrial laser sensor and an Arduino-based solution is one of the most common decision points in distance measurement projects.

This article provides a practical, engineering-focused comparison based on real deployment conditions.

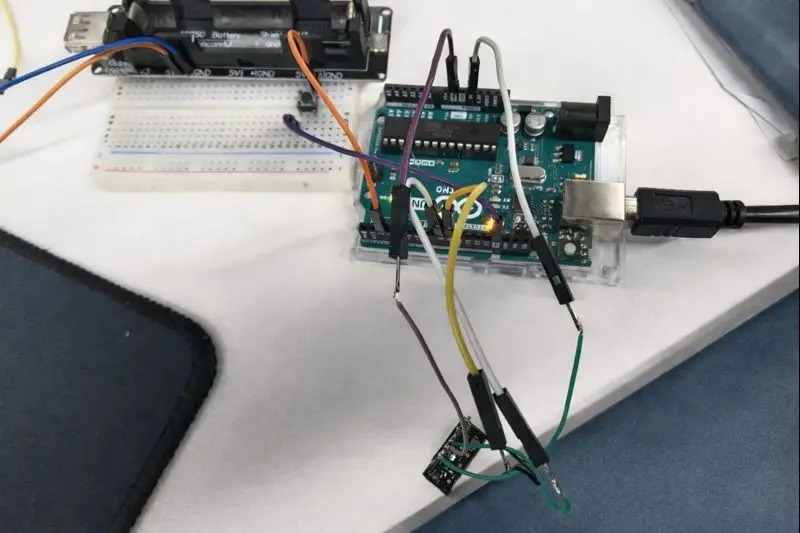

Arduino-Based Distance Measurement: Strengths and Limits

Arduino-based solutions offer:

- Fast setup

- Low entry cost

- High flexibility for prototyping

However, they are limited by:

- Environmental sensitivity

- Inconsistent long-term performance

- Lack of industrial certification

Industrial Laser Sensor: Designed for Deployment

Industrial laser sensors are engineered for:

- Continuous operation

- Electrical and optical noise immunity

- Stable accuracy across temperature ranges

- Industrial communication protocols

Industrial Laser Sensor vs Arduino-Based Solutions: Core Differences

| Criteria | Arduino-Based | Industrial Laser Sensor |

|---|

| Operating environment | Lab / indoor | Indoor & outdoor |

| Accuracy stability | Variable | Stable |

| Interfaces | UART / I²C | RS485 / Modbus |

| EMC compliance | No | Yes |

| Production consistency | Low | High |

To observe real performance differences between simple prototype setups and robust industrial sensors, check Laser distance sensor performance comparison demo.

Choosing the Right Approach

Arduino-based solutions are suitable for:

- Education

- Research

- Early prototypes

Industrial laser sensors are required when:

- Reliability is non-negotiable

- Systems operate 24/7

- Outdoor or harsh environments are involved

This transition is part of the broader evolution described in From Prototype to Industrial Laser Distance Sensors, where performance requirements increase with deployment scale.

Key Takeaway

The choice is not about cost—it is about risk management. Industrial laser sensors reduce technical uncertainty as projects move closer to production.

FAQ

-

Why do Arduino-based laser distance sensors fail in industrial environments?

Arduino-based solutions are sensitive to ambient light, electrical noise, and temperature variation. They also lack industrial certification and robust calibration, making them unsuitable for long-term or safety-critical applications.

-

Is cost the main difference between Arduino-based and industrial laser distance sensors?

Cost is not the primary difference between Arduino-based and industrial laser distance sensors; reliability and long-term stability are more critical factors.

-

Can Arduino-based sensors be used for pilot production?

They may be used in limited pilot setups, but scaling to production usually exposes consistency and reliability issues. Industrial sensors are recommended before volume deployment.

-

What interfaces make industrial laser sensors more suitable for automation?

Industrial laser sensors commonly support interfaces such as RS485, Modbus, or CAN, which are standard in automation and control systems and provide better noise immunity.

-

Is it possible to migrate from Arduino to industrial sensors without redesigning the system?

In many cases, system logic can be reused, but hardware interfaces and signal handling often need adjustment. Planning this migration early reduces integration effort.