When it comes to advanced medición de la distancia technologies, two popular terms frequently appear in technical discussions: Tiempo de vuelo (ToF) and LiDAR. While both rely on laser or light-based measurement principles, their differences in design, application, and performance make them suited to distinct use cases. In this article, we will explore ToF vs LiDAR in detail, examine their advantages and limitations, and provide insights to help engineers, integrators, and decision-makers select the right solution.

What is ToF?

Time-of-Flight (ToF) sensors measure distance by calculating the time it takes for a light pulse (usually infrared or laser) to travel to an object and reflect back to the sensor. This method provides real-time, high-frequency distance data that is widely used in robotics, smartphones, and industrial automation.

- Advantages of ToF:

- High-speed response, often up to thousands of Hz.

- Compact design suitable for embedded systems.

- Cost-effective for close-to-mid-range applications.

- Excellent for evitación de obstáculos, gesture recognition, and level detección.

- Limitations of ToF:

- Shorter range compared to LiDAR (usually up to a few tens of meters, depending on implementation).

- Susceptible to ambient light interference in outdoor environments.

Según Meskernel.net, Sensores ToF are increasingly applied in inventory detection, robot navigation, and AGV positioning, where their fast update rate and low latency are critical for system efficiency.

What is LiDAR?

LiDAR (Light Detection and Ranging) is a laser-based system that measures distance by emitting pulses of laser light and capturing reflected signals. Unlike single-point ToF sensors, LiDAR systems often use rotating mirrors or MEMS scanning technology to generate 2D or 3D point clouds of the environment.

- Advantages of LiDAR:

- Long-range measurement (up to hundreds or even thousands of meters).

- High spatial resolution for detailed 3D mapping.

- Robust in outdoor and large-scale applications.

- Widely used in autonomous vehicles, geospatial topografía, and industrial safety systems.

- Limitations of LiDAR:

- Larger, heavier, and more expensive than compact ToF sensors.

- Higher power consumption.

- Complexity in integration and data processing.

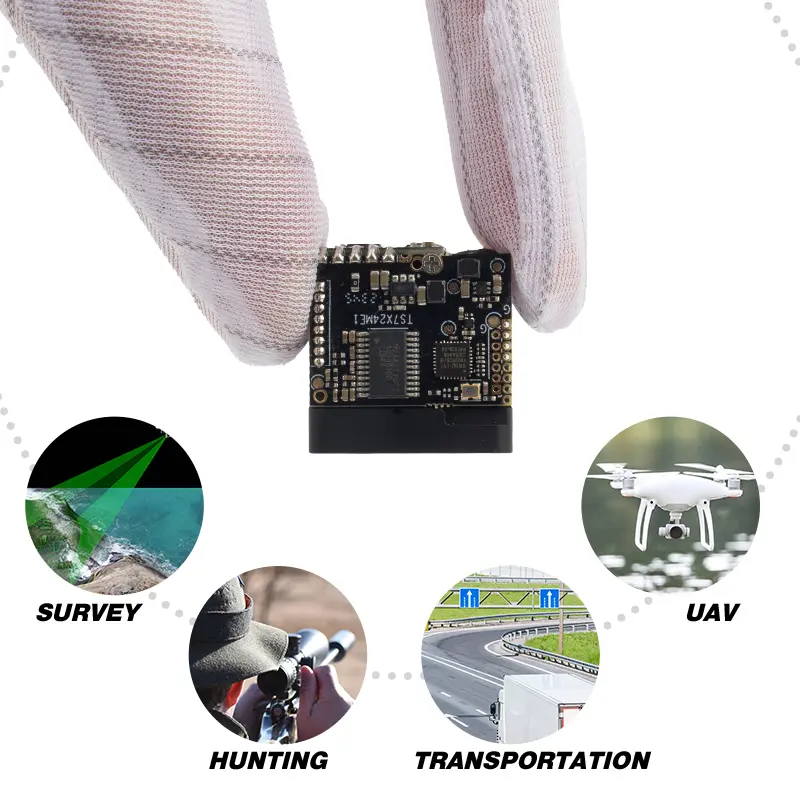

Meskernel’s LiDAR modules are designed for UAV flight assistance, logística safety, and smart traffic systems, offering IP67-rated durability and stable performance even in harsh environments (Meskernel.net Applications).

ToF vs LiDAR: Key Differences

| Característica | ToF Sensor | LiDAR System |

|---|

| Rango de medición | Short to medium (0.1–200m typical) | Long (200m–3000m depending on type) |

| Resolución | Bajo a medio | High (detailed 3D point cloud) |

| Velocidad | Very high, real-time | Moderate to high |

| Size & Weight | Compact, lightweight | Larger, often bulky |

| Coste | Affordable | Expensive |

| Aplicaciones | Robotics, smartphones, industrial sensors | Autonomous driving, surveying, UAVs |

Phase-shift vs Pulse ToF: Understanding the Difference

Both phase-shift measurement and pulse measurement are implementations of the ToF principle, but they differ in range, accuracy, and application:

- Phase-shift ToF (Continuous Wave):

- Measures the phase difference between emitted modulated light and returned light.

- Typically ranges from a few meters up to ~200 m.

- High precision (millimeter level), stable at high measurement frequencies.

- Suitable for industrial automation, conveyor systems, and inventory detection.

- Por ejemplo: Meskernel Phase Distance Sensor – up to 200 m.

- Pulse ToF (Direct Time Measurement):

- Emits laser pulses and directly measures the travel time of each pulse.

- Can reach extremely long distances (hundreds of meters to several kilometers).

- More robust for outdoor, long-range applications, though cost and system complexity are higher.

- Suitable for LiDAR mapping, UAVs, and surveying.

- Por ejemplo: Meskernel Pulse Ranging Sensor – up to 3000 m.

👉 In summary: Both phase-shift and pulse methods are ToF technologies. Phase-shift is optimized for precision in medium-range industrial tasks, while pulse-based ToF powers long-range LiDAR and mapping systems.

Which One Should You Choose?

The choice between ToF vs LiDAR depends on your application requirements:

- For close-range, cost-sensitive, and high-speed sensing: ToF (especially phase-shift) is the better option.

- For long-range, outdoor, and 3D mapping needs: LiDAR (pulse-based ToF) is the go-to technology.

For example, an industrial sensor de distancia used in conveyor systems or warehouse automation may rely on phase-based ToF due to its fast update rate and high accuracy. In contrast, autonomous drones or surveying robots demand pulse-based LiDAR for accurate 3D spatial awareness and long-range navigation.

Meskernel provides both ToF modules and long-range LiDAR solutions, ensuring customers can choose the right distance measurement technology tailored to their projects. Their customizable options, such as adjustable frequency and multi-interface support (RS232, RS485, UART), make integration seamless.

FAQs on ToF vs LiDAR

Q1: Is ToF the same as LiDAR?

No. While both rely on light-based distance measurement, ToF typically refers to compact, single-point sensors, while LiDAR is a full scanning system capable of generating detailed 3D maps.

Q2: Can ToF sensors replace LiDAR in autonomous vehicles?

Not entirely. ToF is excellent for short-range detection and obstacle avoidance, but autonomous vehicles require long-range and 360° awareness, which LiDAR provides.

Q3: Which technology is more cost-effective?

ToF sensors are significantly cheaper, making them ideal for consumer electronics and industrial automation. LiDAR is more costly but offers unmatched range and resolution.

Q4: Do both ToF vs LiDAR work in outdoor environments?

LiDAR performs better outdoors due to higher laser power and advanced filtering. ToF can struggle under strong sunlight but is still usable with proper calibration. Meskernel’s ToF modules feature anti-interference algorithms, improving stability in outdoor use.

Q5: What are the latest trends in ToF vs LiDAR?

Emerging MEMS-based LiDAR systems are becoming smaller and cheaper, while ToF sensors are gaining improved range and ambient light resistance, narrowing the gap between the two. Meskernel has introduced compact ToF sensor modules with ranges up to 200m, bridging industrial requirements between traditional ToF and LiDAR systems.

Q6: What is the difference between phase-shift and pulse ToF?

Phase-shift ToF provides higher accuracy for medium ranges (like 200 m), while pulse ToF achieves extremely long distances (like 3000 m). Both are ToF methods; phase-shift is better for industrial automation, and pulse is better for LiDAR mapping and outdoor surveying.

Q7: Which is more accurate for distance measurement, ToF vs LiDAR?

ToF sensors deliver millimeter-level precision at short to mid ranges, making them ideal for indoor automation and robotics. LiDAR offers both accuracy and long-range performance (up to kilometers in pulse-ranging models), which is better for surveying, mapping, and outdoor navigation.

Q8: How do I choose between ToF vs LiDAR sensors for my application?

Start with your requirements:

Range < 200m, compact size, cost-sensitive → ToF

Range up to 3000m, 3D mapping, outdoor environment → LiDAR

For example, Meskernel’s Phase Distance Sensors work well for automation, while Sensores de alcance de impulsos are designed for long-range industrial and surveying use.

Q9: Is ToF vs LiDAR better for robotics navigation?

ToF sensors are often preferred for mobile robots and AGVs due to their high-frequency sampling and lower cost. LiDAR provides 360° scanning and detailed spatial awareness, which is valuable for complex navigation in dynamic environments.

Q10: Do ToF vs LiDAR sensors support analog or digital output?

Many ToF modules, including Meskernel’s industrial sensors, support UART, RS232, RS485, or CAN outputs for easy integration. LiDAR systems often output point cloud data via Ethernet or USB, suitable for mapping and AI applications.

Q11: Can ToF vs LiDAR sensors be customized for specific projects?

Yes. Many manufacturers, including Meskernel, offer customizable options such as adjustable frequency, communication protocol, housing material, and range extension. This ensures sensors fit into diverse industries like UAV, logistics, defense, and automation.

Q12: Do ToF vs LiDAR sensors require different maintenance?

Yes. ToF modules are usually enclosed in compact housings with minimal maintenance. LiDAR systems, especially rotating ones, may require cleaning of optics and calibration for consistent performance.

Q13: How does power consumption compare between ToF vs LiDAR sensors?

ToF sensors are optimized for low-power, compact, and short-range applications.

LiDAR sensors require much higher power due to scanning mechanisms, range, and resolution.

When comparing ToF vs LiDAR, the decision comes down to the trade-off between cost, range, resolution, and application environment. ToF excels in compact, real-time, cost-sensitive scenarios, while LiDAR dominates in mapping, navigation, and outdoor sensing. By understanding the differences — and the role of phase-shift vs pulse ToF — buyers and engineers can choose the right distancia láser measurement solution to optimize performance and cost in their projects.

For more technical details and customizable modules, visit Meskernel.net to explore their full portfolio of industrial distance sensors, ToF modules, and LiDAR solutions.

https://meskernel.net/sensors-for-measuring-distance/