Preciso medición de la distancia en topografía is the foundation of modern mapping, construcción planning, infrastructure design, and engineering analysis. From determining boundaries to creating digital terrain models, surveyors rely on distance measurements to understand the physical world and convert it into precise, usable data.

With advancing technologies—especially laser-based systems and long-range Tiempo de vuelo (ToF) modules—surveying has become faster, safer, and significantly more efficient. This guide explains how distance measurement works in surveying, what tools are used, the advantages of laser technology, and how to select the right distance measuring instrument for different applications.

1. What Is Distance Measurement in Surveying?

Distance measurement in surveying refers to the process of determining the horizontal, vertical, or sloped distance between two geographical points. This measurement is essential for land mapping, construction layouts, engineering calculations, resource management, and infrastructure design.

Surveyors use various tools—ranging from tapes and optical instruments to medición láser devices and total stations—to obtain reliable distance data. As surveying workflows shift toward automation and digital mapping, laser-based instruments and TOF sensors are becoming the industry standard.

2. Why Distance Measurement Matters in Surveying

Consistent and accurate distance measurement in surveying ensures:

- reliable mapping of natural features and built environments

- proper planning of roads, pipelines, railways, and structures

- safe excavation and earthwork

- correct boundary definition and land subdivision

- accurate height, slope, and alignment calculations

A small measurement error can lead to costly engineering mistakes. That’s why advanced, laser-based tools are rapidly replacing manual or optical methods.

3. Common Methods of Distance Measurement in Surveying

Surveyors use several different measurement techniques depending on range, terrain, and required accuracy.

3.1 Tape Measurement

The traditional method using steel tapes or fiberglass tapes.

Advantages: simple, inexpensive.

Limitations: low accuracy over long distances, sensitive to sag, temperature, and human error.

Suitable for short-distance indoor or flat-field measurements.

3.2 Optical Distance Measurement

Instruments like theodolites and transits estimate distance using stadia readings.

- Requires line of sight and manual calculation

- Dependent on user skill

- Slower compared to modern techniques

Useful in small surveying projects but increasingly outdated.

3.3 Electronic Distance Measurement (EDM)

EDM instruments within total stations use infrared or microwave signals to calculate distance.

- Professional-grade accuracy

- Suitable for land surveying, construction, and geodetic work

- Requires setup and calibration

EDM is a standard part of modern total station systems.

3.4 Laser Distance Measurement

Laser devices are now the most widely used tools for distance measurement in surveying.

Advantages include:

- long-range capability (hundreds to thousands of meters)

- fast single-point and continuous measurement

- high accuracy even in outdoor environments

- lightweight and easy to integrate into surveying equipment

This method is ideal for construction, mapping, UAV surveying, and industrial projects.

3.5 Time-of-Flight (ToF) Distance Sensors

ToF sensors calculate distance based on the time it takes for a laser pulse to return from a target.

- high measurement frequency (10–100 Hz)

- reliable long-range performance

- suited for UAV altitude hold, mining, forestry, and industrial mapping

- integrates well via serial interfaces (UART/RS485/RS232/CAN/analog)

ToF devices are increasingly used in advanced surveying and real-time mapping systems.

4. How Laser Devices Measure Distance

Laser measurement works through several physical principles. Understanding these helps select the right device.

4.1 Time of Flight (ToF)

A laser pulse travels to the target and back.

Distance = (Time × Speed of Light) ÷ 2.

Ventajas:

- supports long ranges (up to 2000–3000 m)

- stable under various outdoor conditions

- ideal for surveying, UAVs, mining, forestry

4.2 Phase-Shift Measurement

Measures the phase difference between emitted and received continuous laser waves.

Ventajas:

- millimeter-level accuracy

- ideal for short to medium distances

- used in high-precision industrial measurement

4.3 Triangulation

Based on laser spot displacement on a sensor.

Ventajas:

- extremely high accuracy

- best for short-distance measurement

- used in industrial and robotic inspection

This method is suitable for precise indoor surveying or structural measurement.

5. Factors Affecting Accuracy in Laser Distance Measurement

Surveying accuracy depends on multiple environmental and technical factors:

- target reflectivity (dark or rough surfaces reduce accuracy)

- strong ambient light interference

- fog, rain, or dust scattering the beam

- optical lens quality and transmittance

- laser power and spot size

- signal processing algorithms

- device stability and mounting angle

Professional distance measuring instruments use multi-echo processing, automatic gain control, and high-efficiency optics to maintain accuracy in challenging outdoor conditions.

6. Types of Distance Measuring Instruments in Surveying

Different projects require different tools. Below are the most common types of instruments used for distance measurement in surveying.

- easy to use

- suitable for building measurement and simple field tasks

- limited range and precision

- long-range capabilities

- accurate outdoor measurement

- ideal for topographic surveying, forestry, and environmental studies

These devices are essential for engineers and survey professionals needing fast, reliable field data.

6.3 Total Stations with EDM

- combines angle measurement + EDM distance measurement

- high accuracy for construction positioning, land boundaries, and infrastructure projects

- requires tripod setup

Total stations remain one of the most widely used surveying tools.

- supports serial interfaces (UART, RS485, RS232, CAN, 0–10 V analógico)

- high-frequency measurement (real-time data)

- ideal for UAV mapping, automation, mining, and large-scale infrastructure surveys

These sensors are increasingly used in advanced surveying systems that demand automation or integration with robotics and drones.

7. Use Cases of Laser Distance Measurement in Surveying

Laser measurement devices are extremely versatile. Below are the most impactful applications across modern surveying industries.

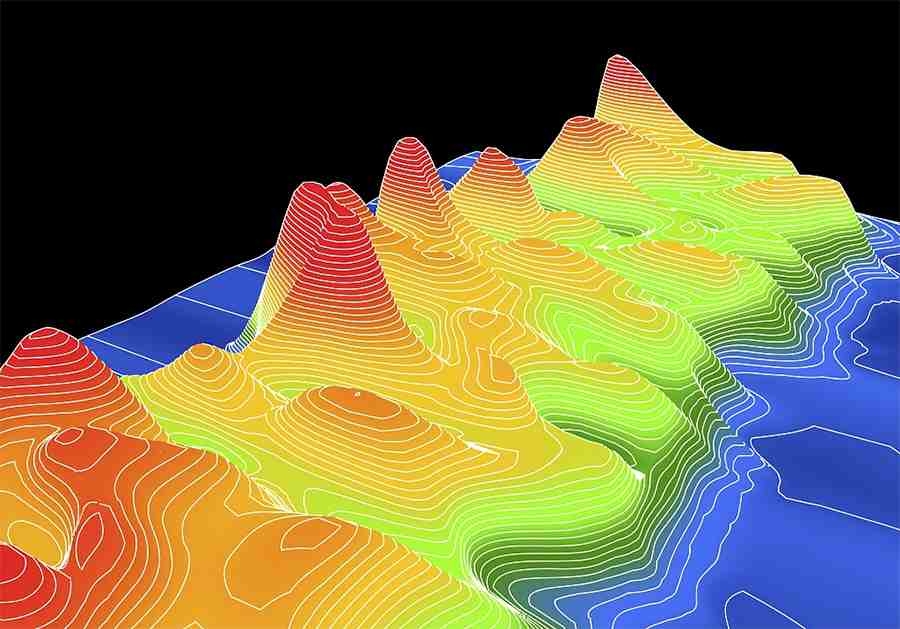

7.1 Topographic and Ground-Based Surveying

Laser-based distance measurement in surveying is the preferred choice for:

- terrain mapping

- slope measurement

- elevation profiling

- digital terrain model (DTM) creation

Surveyors can collect accurate long-range data quickly, even over uneven ground.

7.2 Bridge and Tunnel Engineering

Distancia láser measurement supports:

This is vital for safe and accurate civil engineering.

7.3 UAV Height Control and Terrain Following

Drones rely heavily on laser measurements for:

- altitude hold

- terrain scanning

- LiDAR or photogrammetry assistance

- safe flight in uneven landscapes

- long-range mapping missions

High-frequency ToF sensors ensure stable, real-time altitude data.

7.4 Forestry and Environmental Monitoring

Laser devices enable:

- distance measurement through vegetation gaps

- tree height estimation

- terrain monitoring under dense canopy

- mapping forest boundaries

They perform well even with low-reflective natural surfaces.

7.5 Mining Boundary Measurement and Pit Monitoring

Laser-based surveying ensures:

- accurate pit volume calculation

- slope stability monitoring

- boundary measurement

- long-range scanning in dusty or harsh conditions

These measurements improve both safety and planning.

7.6 Railway and Highway Route Planning

Infrastructure planning requires long-range accuracy.

Medición láser de distancias assists with:

- alignment verification

- slope and terrain assessment

- corridor mapping

- measurement in inaccessible or dangerous areas

Surveyors can capture reliable data without interrupting traffic or exposing staff to hazards.

8. How to Choose the Right Distance Measuring Instrument

When selecting a device for distance measurement in surveying, consider:

- Measurement range (e.g., 0.1–2000 m)

- Accuracy requirements (mm to cm)

- Measurement speed (Hz)

- Interface type (USB, UART, RS485, RS232, CAN, analog)

- Environmental performance (fog, sunlight, dust)

- Optical quality and laser class

- Power consumption (important for UAVs)

- Mounting and integration compatibility

A well-selected instrument reduces data errors and ensures efficient fieldwork.

9. FAQ: Distance Measurement in Surveying

-

What is distance measurement in surveying?

Distance measurement in surveying refers to determining the horizontal, vertical, or sloped distance between two points using tools such as tapes, laser devices, and total stations.

-

Why is laser technology widely used for distance measurement in surveying?

Laser technology offers long-range capability, fast readings, and high accuracy, making it ideal for outdoor surveying where traditional tools struggle.

-

What instruments are commonly used for distance measurement in surveying?

Tools include handheld laser meters, surveying laser rangefinders, total stations with EDM, and long-range ToF sensors.

-

How accurate is laser distance measurement?

High-quality laser devices provide accuracy from millimeters to a few centimeters, depending on range and environmental conditions.

-

Where is laser distance measurement used in surveying?

Applications include topographic mapping, UAV terrain following, mining, forestry, tunnel surveying, and highway/railway planning.

Laser-based distance measurement in surveying has transformed the way engineers, surveyors, and UAV operators capture spatial data. With long-range capability, high precision, and excellent field performance, laser measurement systems are now essential for topographic mapping, civil engineering, forestry, mining, and infrastructure planning.

As surveying demands continue to increase, selecting the right distance measuring instrument—whether a handheld laser, surveying-grade rangefinder, or high-speed ToF sensor—is the key to producing accurate, reliable, and efficient results.