ToF Sensor Accuracy: Unlock Ultra-Precise Distance Measurement

Why Accuracy Matters in ToF Sensing

In precision measurement systems, accuracy is everything. Whether your application involves robot navigation, industrial automation, or level monitoring, even a few millimeters of error can impact system performance and safety.

That’s why understanding ToF (Tiempo de vuelo) sensor accuracy—and knowing how to optimize it—is critical for engineers choosing the right ToF range sensor or distancia láser measurement module.

Unlike traditional triangulation or phase-based sensors, Sensores ToF calculate distance by measuring the travel time of emitted light pulses. This makes them highly responsive and suitable for both short and long-range measurement. But accuracy can vary based on several environmental and design factors.

1. Key Factors Affecting ToF Sensor Accuracy

1.1 Reflectivity of the Target Surface

The reflectivity or color of the target object directly affects the signal strength received by the ToF module.

- Bright or white surfaces reflect light efficiently, resulting in stronger signals and higher accuracy.

- Dark, matte, or absorbent materials can reduce reflected intensity, leading to increased Sensor ToF measurement error.

👉 Consejo: For critical measurements, use retroreflective targets or increase the laser power if your application allows.

1.2 Distance and Signal Strength

As the measurement distance increases, the returning light intensity decreases.

A ToF range sensor typically maintains high precision within its rated range, but accuracy degradation occurs beyond 80–90% of maximum distance.

For instance, the Meskernel LDL40 Series ToF Sensors maintain ±1 mm precision up to 40 meters, outperforming many standard industrial modules.

1.3 Ambient Interference (Light, Dust, and Reflective Backgrounds)

Strong ambient light—especially sunlight—can introduce background noise that confuses the sensor’s receiver. Similarly, dust particles or reflective surroundings can cause multiple reflections, leading to false readings.

💡 Best practice: Use optical filters and modulated signals to minimize interference. Meskernel’s industrial ToF sensors are designed with advanced optical filtering and anti-interference algorithms for reliable performance in outdoor and factory environments.

1.4 Sensor Frequency and Integration Time

The measurement frequency (or sampling rate) also affects accuracy.

Higher frequency means faster updates—but potentially more noise.

Longer integration times allow for better averaging and less random error, improving ToF sensor accuracy in stable applications.

For dynamic systems such as AGVs or drones, it’s best to balance between speed and precision depending on movement and response needs.

Arduino Sensores láser de distancia

Arduino Sensores láser de distancia

sensor láser de largo alcance

sensor láser de largo alcance

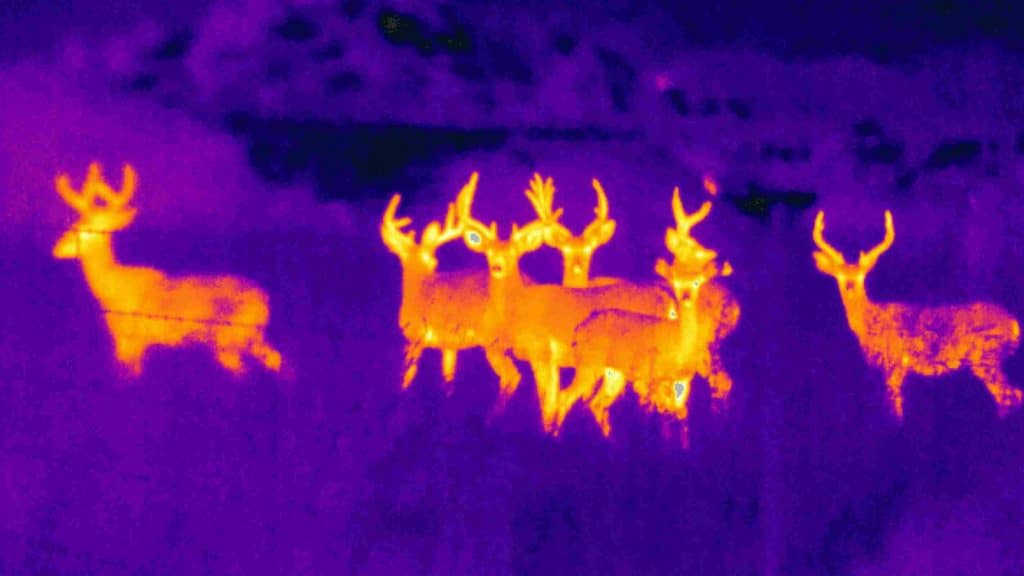

Láser Sensor de distancia para Animal Detection

Láser Sensor de distancia para Animal Detection

1.5 Temperature and Environmental Stability

Temperature fluctuations can slightly change the refractive index of air and affect laser timing circuits. High humidity or vibration can also introduce ToF sensor module drift over time.

🧠 Engineering tip: Perform temperature calibration during setup and periodically re-calibrate if the system operates under varying environmental conditions.

2. Interpreting Measurement Metrics and Specifications

Manufacturers may list accuracy as ±mm (absolute) or as a percentage of range.

For example:

- ±1 mm (fixed) — consistent across range

- ±0.1% of distance — varies with target range

When comparing tof sensor accuracy, always check:

- En reference reflectivity used in testing (e.g., 90% white target)

- En measurement frequency

- En temperature range

You can explore a detailed explanation of these parameters in our ToF sensor accuracy deep-dive.

3. Best Practices to Optimize ToF Sensor Accuracy

To achieve best-in-class precision, consider the following optimization practices:

- Calibrate your ToF sensor using known reference targets at various distances.

- Stabilize the sensor mechanically—vibration can cause fluctuating readings.

- Filter raw measurement data using median or moving average filters.

- Align the sensor perpendicular to the target surface.

- Avoid strong reflective backgrounds that may scatter light.

- Control temperature and provide shielding in outdoor setups.

- Update firmware regularly for optimized signal processing algorithms.

With proper setup, ToF sensor accuracy can achieve sub-millimeter levels even in dynamic industrial settings.

4. Meskernel’s Accuracy Performance

At Meskernel, we design our laser ToF sensores with high-performance optical components and stable calibration algorithms.

Nuestra LDL Series offers:

- ±1 mm accuracy up to 40 m

- Clasificación IP67 housing for harsh environments

- 100 Hz measurement rate for real-time feedback

- Built-in temperature compensation and signal filtering

See detailed specifications and accuracy comparisons in our Best ToF Sensor Guide.

FAQ: ToF Sensor Accuracy Explained

Q1: What affects ToF sensor accuracy the most?

The main factors are target reflectivity, measurement distance, and ambient light interference. Ensuring proper calibration and alignment can greatly improve accuracy.

Q2: How can I improve ToF range sensor performance outdoors?

Use sensors with ambient light suppression and temperature compensation. Also, add optical filters and shield the receiver from direct sunlight.

Q3: Why do my ToF sensor readings fluctuate?

Variations often result from vibration, electrical noise, or surface texture. Apply digital filtering and ensure the sensor is firmly mounted.

Q4: What’s the difference between ToF accuracy and resolution?

Accuracy measures how close the reading is to the true distance, while resolution defines the smallest detectable change. A sensor may have 1 mm resolution but 2 mm accuracy depending on setup.

Q5: Which Meskernel ToF sensor is best for high-precision applications?

En LDL Series y LDLG-P4 Green Laser Model provide excellent precision for both short- and long-range measurement, ideal for robotic positioning, industrial inspection, and level control.

Next Steps

ToF sensor accuracy depends on a balance of hardware quality, environment, and calibration. By understanding the influencing factors and implementing best practices, you can minimize ToF sensor measurement error and achieve consistent, repeatable results.

Explore our full range of high-accuracy ToF distance sensors and application examples at:

👉 Meskernel ToF Sensor Applications

https://meskernel.net/time-of-flight-distance-sensor/