Fast & Accurate Height Sensor for Industrial Measurement

In the world of industrial automation, precision is power. Whether you’re monitoring the height of products on a conveyor line, controlling robotic arms, or ensuring safety in dynamic environments, capteurs laser for mesure de la distance deliver the speed and accuracy needed for modern production systems.

This article explores how height sensors, fast measuring distance sensors, and high-accuracy laser measuring devices work across different industrial applications — from height détection to safety monitoring — and why they’ve become the gold standard in mesure sans contact.

1. Understanding Distance and Height Sensors

Distance sensors are designed to detect and measure the distance between the sensor and a target surface. When used for vertical measurement, these devices are known as height sensors or distance sensors for mesure de la hauteur, widely applied in:

- Level and height control in packaging and warehousing

- Material thickness or stacking height detection

- Position feedback for robotics and automation lines

- Object detection in AGV (Automated Guided Vehicle) systems

Laser-based sensors operate on Time of Flight (ToF) or Triangulation principles. The sensor emits a laser beam that reflects off the target surface; the return time or phase shift determines the exact distance — enabling non-contact, high-precision measurement.

2. Why Choose a Laser Sensor for Distance Measurement

Distance du laser sensors offer several advantages over ultrasonic or infrared alternatives:

- ⚡ Fast Response Speed: Real-time detection for moving or rotating targets

- 🎯 Haut Précision de la mesure: Up to ±1 mm precision, ideal for fine control

- 🌍 Long Range Detection: From a few centimeters to over 200 meters

- 💪 Mesure sans contact : Perfect for hot, fragile, or contaminated surfaces

- 🧠 Smart Integration: Compact structure for OEM modules and automation systems

These benefits make laser measuring devices the preferred choice for industrial automation, robotics, la logistique, and precision manufacturing.

3. Fast Measuring Distance Sensors: Speed Meets Reliability

Speed is crucial for maintaining productivity. A fast measuring capteur de distance can reach frequencies up to 10000 Hz, ensuring real-time performance even when measuring moving targets.

For example, Meskernel’s capteur de distance laser combines:

- 10000 Hz high-frequency measurement

- Green laser for enhanced visibility and reflectivity

- IP54-rated housing for industrial durability

- Stable accuracy under varying ambient light

This type of sensor is ideal for robot alignment, height monitoring, and industrial quality inspection — where both speed and precision are essential.

4. High-Accuracy Distance Sensors for Industrial Applications

When every millimeter matters, high-accuracy distance sensors deliver. These sensors achieve sub-millimeter precision using iToF (Indirect Time of Flight) or phase-shift technology.

They’re widely used for:

- Dimensional measurement and quality inspection

- Position control in CNC and robotic applications

- Alignment and calibration in automated assembly lines

- Feedback systems for real-time machine control

By minimizing environmental interference, these industrial Détecteurs de distance à laser maintain accuracy under diverse lighting, surface, and temperature conditions.

5. Typical Industrial Applications of Laser Distance and Height Sensors

1. Position Alignment (Robot Alignment Sensor)

In robotic automation, precision alignment is critical. A laser distance sensor for robot alignment continuously measures the target distance, allowing robotic arms or assembly systems to automatically correct their position — improving accuracy and reducing calibration time.

2. Height Detection (Height Sensing Sensor)

A height sensor for industrial use detects even the smallest variation in surface level. These sensors are used to:

- Verify if a product is correctly positioned

- Measure stacking height on pallets or conveyors

- Ensure consistent filling levels in containers

This enables consistent product quality and precise automation control.

3. Process Monitoring (Process Control Laser Sensor)

During welding, cutting, or grinding, laser measuring devices monitor the target’s position in real-time, ensuring that the workpiece stays within the correct focus or tolerance range. This non-contact measurement improves safety and process repeatability.

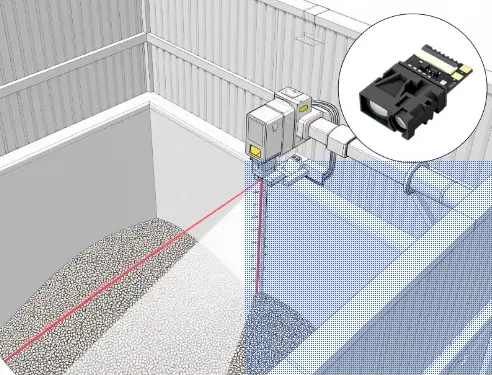

4. Safety Control (Industrial Safety Distance Sensor)

In high-speed production lines or robotic work cells, distance sensors for safety control detect obstacles or human presence. When an object or person enters a restricted area, the system can instantly trigger an emergency stop, ensuring safe operation.

6. How to Choose the Right Laser Measuring Device

Selecting a mesure de la distance par laser device depends on your application needs:

- Plage de mesure : Short-range (0.1–30m) or long-range (up to 200m)

- Speed & Frequency: Dynamic vs. static target measurement

- Exigences de précision : ±1 mm, ±3 mm, or higher tolerance

- Type de sortie: Analogique, RS485, UARTou numérique sortie

- Environmental Protection: IP54 / IP65 for industrial conditions

If your system demands fast, precise, and stable performance, Meskernel’s laser sensors provide a versatile solution for both OEM and industrial integrations.

7. Future Trends in Laser Distance Measurement

Emerging technologies are making laser distance sensors even smarter:

- Integration with AI for self-calibration

- Miniaturized modules for embedded IoT devices

- Enhanced ambient light immunity

- Multi-sensor synchronization for 3D profiling

As smart factories and autonomous systems evolve, high accuracy laser measuring devices will continue to play a vital role in precision-driven industries.

Conclusion

From robotic alignment to safety monitoring, laser sensors for distance measurement are transforming how industries measure, monitor, and maintain precision.

Whether your goal is fast measuring, high accuracy, or non-contact height detection, advanced laser distance sensors deliver unmatched performance and reliability.

Explore the latest innovations at Capteurs de distance à laser Meskernel — and take precision to the next level.

FAQs About Height Sensors and Laser Distance Measurement

-

What is a Height Sensor and How Does It Work?

A height sensor is a laser-based measuring device that determines the vertical distance between the sensor and a target surface.

It works using Temps de vol (ToF) or Triangulation technology — the sensor emits a laser beam, which reflects back from the object.

By calculating the time it takes for the laser to return, the sensor provides a precise, non-contact height measurement with millimeter accuracy.

-

What’s the Difference Between a Height Sensor and a Distance Sensor?

A distance sensor measures the space between two points in any direction, while a height sensor is specifically designed to measure vertical displacement or object height.

In most industrial systems, both are actually the same device — a laser distance sensor configured for height measurement applications such as object detection, level control, or alignment.

-

Why Should I Choose a Laser Height Sensor Instead of Ultrasonic or Infrared Sensors?

A laser height sensor offers several advantages:

Much higher accuracy (±1 mm or better)

Faster response for moving targets

Longer measuring range (from a few centimeters up to hundreds of meters)

Non-contact detection that works even with hot, shiny, or rough surfaces

These benefits make laser sensors for distance and height measurement ideal for industrial automation, robotics, and quality inspection.

-

What Are the Typical Applications of a Laser Height Sensor?

Height sensors are used in a wide range of industrial and automation fields, including:

Height control on conveyor lines or filling machines

Position alignment for robotic arms and CNC systems

Process monitoring during welding, cutting, or grinding

Safety protection — detecting obstacles or human presence near machines

In each case, the sensor ensures fast, stable, and reliable measurement even in harsh conditions.

-

How Accurate Are Meskernel Laser Height Sensors?

Meskernel’s high-accuracy laser height sensors use advanced iToF (Indirect Time of Flight) technology to achieve sub-millimeter precision.

They maintain consistent results regardless of lighting, temperature, or surface reflectivity — ensuring performance stability in demanding environments.

-

What Should I Consider Before Buying a Height Sensor?

Before purchasing, consider:

Measuring range: How far does the sensor need to measure?

Speed requirements: Static or fast-moving targets?

Accuracy tolerance: ±1 mm, ±3 mm, or higher?

Output type: Analog, RS485, or UART digital output?

L'environnement : Need IP54 or IP65 protection for dust and water resistance?

If you need help selecting the right model, contact Meskernel’s technical team for professional guidance.

-

Can Laser Height Sensors Be Integrated Into Existing Systems?

Yes. Most industrial laser height sensors come in compact modules with multiple output options, allowing easy integration into PLCs, robotic systems, or custom OEM designs.

Meskernel provides flexible models that support analog voltage, current, or serial communication for seamless system compatibility.

-

Are Laser Height Sensors Suitable for Outdoor or Harsh Environments?

Absolutely. Meskernel’s industrial-grade height sensors are built with IP54–IP65 protection, offering resistance to dust, vibration, and temperature fluctuations.

They perform reliably both indoors and outdoors, even under direct sunlight or reflective surfaces.

https://meskernel.net/industrial-laser-distance-sensor/