Introduction

In industries such as cold chain, warehousing, industrial automation, and logistics, the ability to monitor distance and levels accurately is essential. Many companies looking to integrate mesure de la distance technology often think they need a complete turnkey system—motherboard, communications, and AI software included. However, the true foundation of such solutions lies in the LiDAR capteur de distance module. With the right OEM or custom sensor, you gain flexibility and reliability while leaving room to integrate into your existing ecosystem. This article will explain why OEM & custom LiDAR distance sensor modules matter, what you should prepare before customization, and how Meskernel can support your project.

1. Why OEM LiDAR & Laser Distance Sensors Matter

Flexibility: Each application comes with unique requirements for range, precision, and communication protocols. OEM sensors allow you to fine-tune specifications to fit your exact scenario.

Integration: The sensor acts as the “eyes” of your system, providing accurate readings that can be integrated with motherboards, communication systems (WiFi, 4G), and AI inventory management.

Cost Efficiency: By sourcing just the measurement core, you reduce costs compared to investing in complete systems, while gaining more control over hardware integration.

Clarity vs. Generic OEM Sensors: While OEM sensors can include temperature, pressure, or motion devices, an OEM LiDAR distance sensor is specifically designed for high-accuracy distance measurement. This makes it the right choice for inventory and level détection projects.

2. Key Parameters to Define Before Customization

When discussing OEM or custom modules, it’s crucial to prepare the following information:

- Operating Temperature Range: Will the sensor work in a freezer, outdoors, or high-temperature environments?

- Measurement Distance Range: What is the typical distance from the sensor to the target surface (e.g., 0.1–30m or longer)?

- Accuracy/Resolution: Do you require ±1mm accuracy, or higher precision for sensitive applications?

- Environmental Conditions: Will the sensor be exposed to frost, humidity, dust, or vibration?

- Expected Order Quantity: Both your initial volume and forecasted scale-up matter for customization and cost optimization.

Defining these parameters ensures that the chosen module is not only technically suitable but also economically viable.

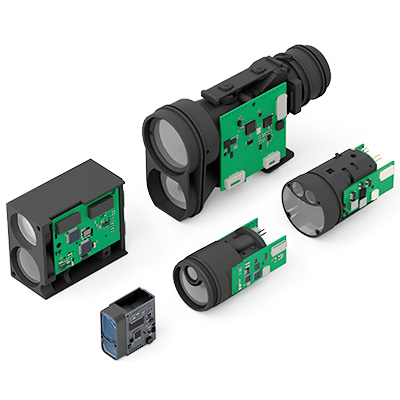

3. OEM & Customization Options from Meskernel

At Meskernel, we focus on tailoring LiDAR and capteur de distance laser modules to your project’s needs. Our capabilities include:

- Hardware Customization: Board dimensions, communication interfaces (UART, RS485, CAN, Ethernet), and power supply compatibility.

- Performance Tuning: Adjustment of range, accuracy, and measurement refresh rate.

- Firmware Adjustments: Custom data output formats, filtering algorithms, and anti-interference optimization.

- Environmental Design: Protection ratings (IP65/IP67), extended temperature tolerance, and housing for high-moisture or dust-prone environments.

These options allow system integrators to seamlessly embed our modules into their own platforms.

4. Application Example: Ice Freezer Inventory Monitoring

Scenario: A distribution company needs to monitor ice bag inventory inside freezers to improve replenishment schedules.

Challenge: Freezer environments involve low temperatures, moisture, and sometimes frost build-up. Despite these conditions, accurate level detection is essential.

Solution: A Meskernel OEM LiDAR module is installed inside the freezer. The sensor measures the distance from the top of the freezer to the ice pile surface, converting it into inventory levels. The data is integrated with the customer’s motherboard and communication systems (WiFi/4G) and tied into sales and replenishment software.

Outcome:

- Accurate, real-time stock monitoring

- Reduced manual checking

- AI-driven predictions for refill quantities

- Streamlined supply chain efficiency

This example illustrates how a custom LiDAR distance sensor module can become the foundation of a smart inventory management solution. Beyond freezers, similar applications include warehouse stock monitoring, industrial automation systems, and UAV altitude measurement.

5. How to Get Started with Meskernel OEM Sensors

Collaborating with us is straightforward:

- Share Your Requirements: Provide details on environment, accuracy, range, and conditions.

- Define Order Quantity: Let us know your initial needs and projected scaling plans.

- Receive Recommendation: We’ll propose the most suitable module and customization options.

- Prototype & Testing: Validate performance in your application environment.

- Mass Production: Move from prototype to scaled deployment.

Conclusion

OEM & custom LiDAR distance sensor modules are the core building blocks of modern measurement and monitoring systems. By clearly defining your requirements and collaborating with a specialized provider like Meskernel, you can reduce integration risks, accelerate development, and build solutions that truly fit your industry’s needs.

Whether you search for OEM sensors, LiDAR modules, or custom distance measurement solutions, the foundation always comes down to the right distance sensor module.

👉 Interested in exploring OEM or LiDAR distance sensors for your project? Contact Meskernel today to discuss your customization options.

FAQ: OEM Sensors vs. LiDAR Distance Sensors

Q1: What is the difference between an OEM sensor and an OEM LiDAR distance sensor?

Answer: An OEM sensor is a general type of sensor and can measure temperature, pressure, acceleration, humidity, and more. An OEM LiDAR distance sensor is specifically designed for non-contact distance measurement and is ideal for inventory monitoring, automation, and industrial measurement.

Core focus: Distance measurement → LiDAR is more accurate.

Q2: What is the typical measurement accuracy of an OEM LiDAR distance sensor?

Answer: Accuracy typically ranges from ±1 mm to ±30 mm, depending on customization. Consider the application environment, such as indoor/outdoor, low temperature, dust, or humidity, when selecting a sensor.

Q3: Can LiDAR distance sensors work in extreme environments?

Answer: Yes. With custom IP65/IP67 packaging and extended temperature ranges, LiDAR modules operate reliably in:

1.Freezers or cold storage

2.Humid environments

3.Dusty or harsh industrial conditions

Q4: What information should I prepare before requesting an OEM sensor?

Answer: To ensure accurate customization, prepare:

1.Operating temperature range

2.Measurement distance range

3.Accuracy and resolution requirements

4.Environmental conditions (frost, humidity, vibration)

5.Expected order quantity

Q5: How does customization affect cost and lead time?

Answer:

Initial sample development can take weeks to months, depending on complexity.

Bulk orders reduce unit cost: larger volume → better cost efficiency.

Q6: What applications can OEM LiDAR distance sensors be used for?

Answer: Common applications include:

1.Freezer inventory monitoring

2.Warehouse stock level detection

3Industrial automation and robotics

4.UAV/drone altitude measurement

5.Smart city and IoT systems