Infrared Sensors vs. Laser Distance Sensors: Understanding the Key Differences

When it comes to measuring distances or detecting objects in various applications, two of the most commonly used sensors are infrared sensors and laser distance sensors. Both technologies serve similar purposes, but they operate differently and are suited to distinct use cases. In this article, we will explore the main differences between infrared sensors and laser distance sensors, helping you choose the right solution for your needs.

1. Working Principle: How They Operate

Laser Distance Sensors use laser beams, to precisely measure distances by calculating the time it takes for light to bounce back, enabling accurate 3D mapping and object detection. In contrast, infrared sensors detect reflected infrared light or heat emissions, making them suitable for basic proximity sensing and thermal imaging.

2. Accuracy and Precision

One of the major differences between infrared sensors and laser distance sensors is their accuracy.

- Infrared Sensors typically have lower accuracy and precision. They often operate with tolerances of a few centimeters, which makes them suitable for basic applications like presence detection or rough distance measurement.

- Laser Distance Sensors, however, provide much higher accuracy—often down to the millimeter level. This makes them ideal for applications requiring precise distance measurements, such as in industrial automation, robotics, or surveying.

3. Measurement Range

The measurement range is another important factor to consider.

- Infrared Sensors generally work well over shorter distances, typically ranging from a few millimeters to a few meters. This makes them ideal for close-range detection, such as detecting obstacles in a robot’s path or monitoring the level of a liquid in a container.

- Laser Distance Sensors can measure much longer distances, from a few centimeters to hundreds of meters, depending on the model. This extended range is ideal for tasks like building measurement, outdoor distance detection, and even autonomous vehicle navigation.

4. Environmental Factors

Both sensors are sensitive to environmental conditions, but each has its own strengths and weaknesses.

- Infrared Sensors are highly sensitive to changes in ambient light and temperature. Direct exposure to sunlight or varying temperatures can affect their accuracy and reliability. Furthermore, reflective surfaces or highly absorbing objects can also impact their performance.

- Laser Distance Sensors are less affected by ambient light, and modern models are designed to be stable in a range of environments, from extreme temperatures to outdoor conditions with varying light. They can deliver consistent performance even in bright sunlight or in low-light settings, thanks to their focused beam.

5. Cost

The cost of infrared sensors is typically lower than laser distance sensors, making them more affordable for simpler applications where high accuracy isn’t crucial. Infrared sensors are commonly used in everyday devices such as motion detectors, presence sensors, and basic proximity sensors.

In contrast, laser distance sensors are more expensive due to their higher accuracy, extended range, and more complex technology. However, the investment is worth it for high-precision applications like industrial measurement, geospatial mapping, or autonomous systems, where accuracy and long-range detection are crucial.

6. Applications

Each sensor type excels in different fields.

- Infrared Sensors are commonly found in applications such as:

- Proximity detection (e.g., automatic doors, presence detection)

- Temperature sensing (e.g., in thermometers)

- Simple distance measurement (e.g., in basic consumer electronics)

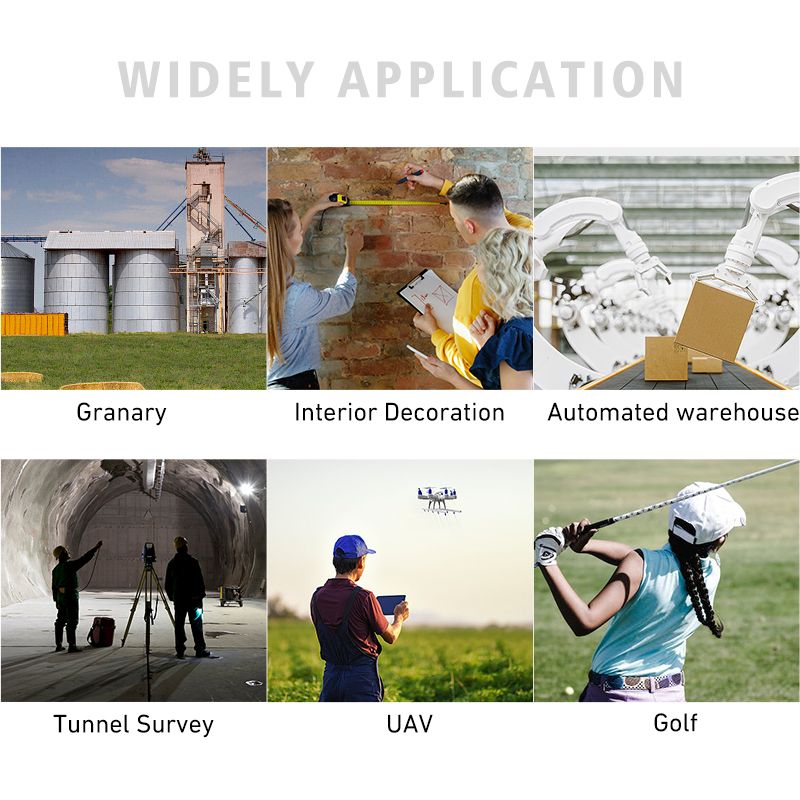

- Laser Distance Sensors are used in more advanced applications, including:

- Industrial automation (e.g., precise measurement in manufacturing)

- Robotics (e.g., navigation and obstacle avoidance)

- Surveying (e.g., land measurement and mapping)

- Automotive applications (e.g., LIDAR for autonomous vehicles)

7. Summary Table: Quick Comparison

| Feature | Infrared Sensors | Laser Distance Sensors |

|---|

| Working Principle | Reflection of infrared light | Time-of-Flight (ToF) or phase-shift |

| Accuracy | Lower precision (centimeters) | High precision (millimeters) |

| Measurement Range | Short range (mm to a few meters) | Long range (cm to hundreds of meters) |

| Environmental Sensitivity | Affected by light and temperature changes | Less affected by environmental conditions |

| Cost | Low cost | Higher cost due to precision and range |

| Typical Applications | Proximity detection, motion sensing | Industrial measurement, robotics, surveying |

Which Sensor Should You Choose?

- If you need a simple, cost-effective solution for detecting nearby objects or measuring short distances, an infrared sensor might be the right choice. It is perfect for applications where high accuracy isn’t critical, such as motion sensing or basic proximity detection.

- For applications requiring high precision and long-range measurement, a laser distance sensor is the better option. Its accuracy, long-range capabilities, and adaptability to various environmental conditions make it ideal for industrial, robotic, and surveying applications.

At the end of the day, the choice between an infrared sensor and a laser distance sensor depends on your specific application requirements—from the range and accuracy to environmental factors and budget. By understanding these differences, you can make an informed decision to achieve the best performance for your project.

Feel free to contact us if you need assistance choosing the right sensor for your needs. As a leading manufacturer of laser distance sensors, we provide custom solutions to meet any challenge in the most demanding environments.

Learn More About Our Custom Sensor Services