From prototype to industrial distanza laser sensors, engineers often face challenges when transitioning from early testing to stable, long-term deployment. This guide explains how to choose the right solution at each stage.

How to Choose the Right Sensor for Real-World Applications

Sensori di distanza laser are widely used in automation, robotics, smart infrastructure, and industrial measurement systems.

However, many projects fail or stall during the transition from prototype testing to real industrial deployment.

This guide explains how laser distance sensing solutions evolve—from prototype and Arduino-based setups to industrial-grade and OEM laser sensore di distanza modules—and what engineers should consider at each stage to avoid costly redesigns.

1. Prototype Laser Distance Sensor: Where Most Projects Begin

Prototype laser distance sensors are commonly used during early-stage development to validate measurement principles, algorithms, and system layouts. At this stage, flexibility and fast iteration are prioritized over long-term stability or environmental robustness.

Common Prototype Laser Distance Sensor Choices

These solutions are ideal for:

Why Prototype Sensors Work — and Why They Eventually Fail

Prototype laser distance sensors are usually sufficient in controlled environments, but problems often appear when moving beyond the lab:

- Sensitivity to ambient light

- Limited measurement stability

- Inconsistent accuracy over time

- Lack of industrial communication interfaces

- No long-term calibration guarantee

A prototype that performs well indoors may become unreliable when exposed to temperature variation, vibration, or continuous operation.

For more details on early development options and limitations, see our guide on prototype laser distance sensors.

2. Industrial Laser Sensor vs Arduino-Based Solutions

Arduino-based distance measurement solutions are widely used in prototyping, but their limitations become apparent in real-world deployment. This section compares Arduino-based setups with industrial laser distance sensors from a practical engineering perspective.

Practical Comparison

| Aspect | Arduino / Prototype Setup | Industriale Sensore di distanza laser |

|---|

| Continuous operation | Limited | Designed for 24/7 use |

| Ambient light immunity | Basso | Alto |

| Measurement stability | Variable | Factory-calibrated |

| Interfacce | UART, I²C | RS485, Modbus, CAN |

| EMC compliance | Not certified | Industrial-grade |

| Installazione | Development-level | Deployment-ready |

When Arduino Is No Longer Enough

If your project involves:

- Outdoor measurement

- Safety-critical distance monitoring

- Production-scale deployment

- OEM integration

Then an sensore laser industriale di distanza is no longer an upgrade—it is a requirement.

To explore a detailed comparison of prototyping solutions and production-ready options, read industrial laser sensor vs Arduino-based solutions.

3. Key Requirements for Industrial Laser Distance Sensors

Industrial applications demand consistency and reliability beyond what prototype sensors can deliver.Industrial laser distance sensor specifications

Core Industrial Requirements

- Stable accuracy over temperature

- Resistance to sunlight and electrical noise

- Long-term calibration stability

- Standard industrial protocols

- Predictable lifecycle and supply continuity

Industrial laser distance sensors are engineered with:

- Optimized optical filtering

- Robust signal processing

- Strict quality control during production

These design choices directly address real-world deployment challenges.

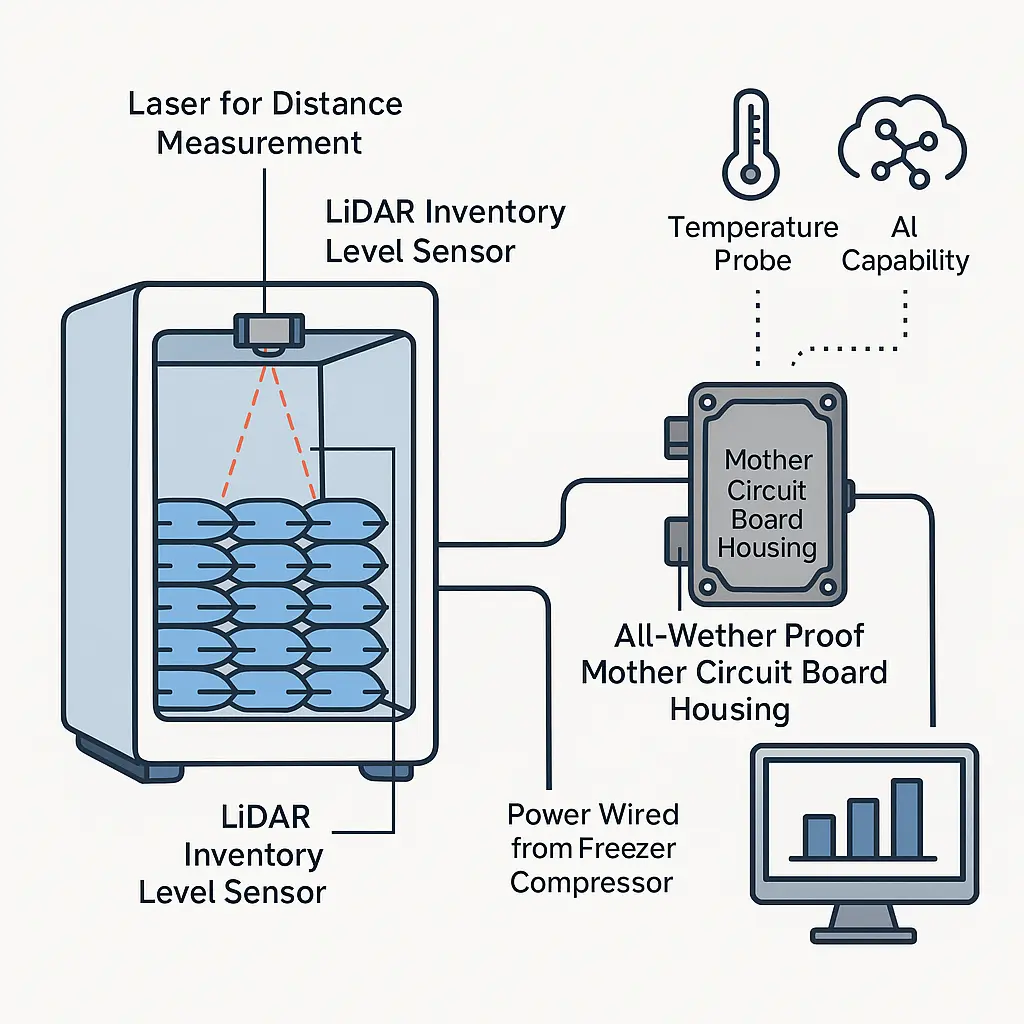

4. OEM Laser Distance Sensor Modules for System Integration

OEM laser distance sensor modules are typically introduced after prototype validation, when system requirements are fixed and production planning begins. They are designed for direct integration into industrial equipment and embedded systems.

Why Choose an OEM Laser Distance Sensor Module?

OEM modules are ideal when:

- Space is limited

- Custom housings are required

- System-level integration is needed

- Large production volumes are planned

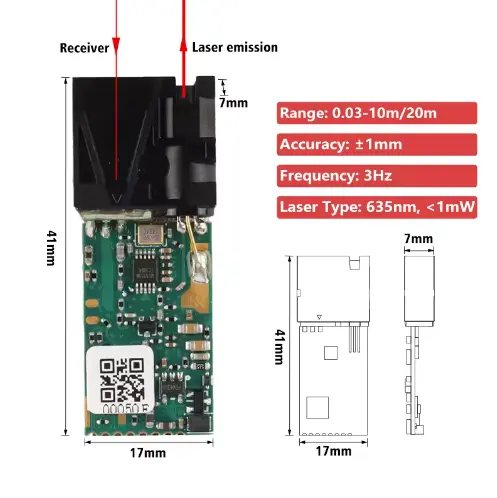

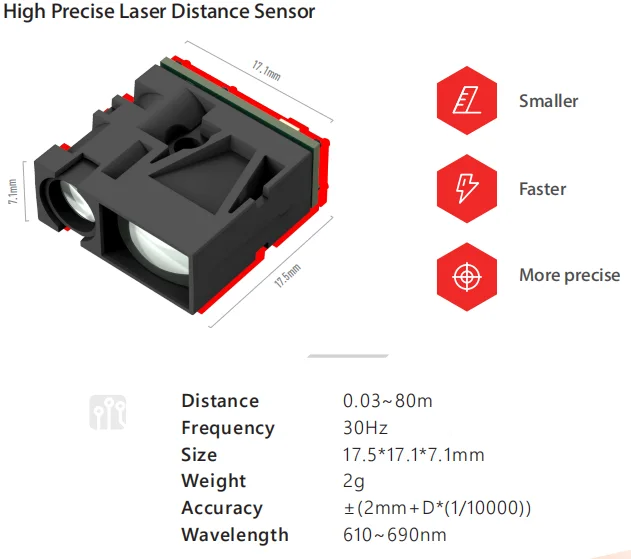

Key Considerations for OEM Selection

When selecting an OEM modulo sensore di distanza laser, engineers should evaluate:

- Mechanical dimensions

- Interface compatibility

- Optical wavelength and power

- Measurement range and resolution

- Batch-to-batch consistency

- Long-term availability

OEM modules are not just components—they are core measurement subsystems within your product.OEM laser distance sensor integration options

For comprehensive guidance on selecting and integrating sensor modules into your system, see our article on OEM laser distance sensor modules.

5. Long Range Laser Distance Sensors for Outdoor Applications

Long-range distance measurement in outdoor environments introduces challenges such as sunlight interference, weather conditions, and target reflectivity. Industrial laser distance sensors are specifically designed to address these issues.Long range outdoor laser distance sensor performance.

Challenges in Outdoor Long-Range Measurement

- Strong sunlight interference

- Target reflectivity variation

- Rain, fog, and dust

- Alignment drift over distance

Hands-on laser distance sensor demo in real environment

Industrial long range laser distance sensors use:

- Narrow-band optical filters

- Optimized receiver sensitivity

- Advanced signal algorithms

- Controlled laser emission for Class 1 safety

These features enable reliable performance in applications such as:

- AGV and AMR navigation

- Sistemi di traffico intelligenti

- Crane positioning

- Stockpile and silo measurement

To understand distance measurement over long ranges in outdoor conditions, refer to long range laser distance sensors for outdoor use.

6. Transitioning from Prototype to Industrial Deployment

The transition from prototype to industrial deployment should be planned early.

Signs You Are Ready to Upgrade

- Field tests show inconsistent results

- Environmental factors affect accuracy

- Production scaling is planned

- Customers demand higher reliability

Recommended Transition Strategy

- Validate measurement principles with prototype sensors

- Test industrial sensors in parallel

- Select OEM modules for final integration

- Lock specifications before mass production

This approach reduces redesign costs and shortens time to market.

7. How to Prepare for an Industrial Laser Distance Sensor RFQ

Before requesting a quotation, it is helpful to define:

- Measurement range

- Accuracy and repeatability

- Operating environment

- Interface requirements

- Expected production volume

Clear technical requirements allow suppliers to recommend the most suitable industrial or OEM laser distance sensor solution.

Conclusion: Choosing the Right Laser Distance Sensor at Each Stage

Prototype laser distance sensors are essential for innovation, but industrial applications require industrial-grade performance.

Understanding the differences between:

- Prototype sensors

- Arduino-based solutions

- Industriale sensori laser

- OEM laser distance sensor modules

helps engineers design systems that scale reliably from lab testing to real-world deployment.

Choosing the right sensor early is not just a technical decision—it is a strategic one that directly affects product success.

If you are evaluating industrial or OEM laser distance sensors for your application, detailed specifications and integration guidance are essential for the next step.

FAQ – From Prototype to Industrial Laser Distance Sensors

-

What is the main difference between prototype and industrial laser distance sensors?

Prototype laser distance sensors are designed for flexibility and rapid testing, while industrial laser distance sensors are engineered for long-term stability, environmental robustness, and continuous operation. Industrial sensors typically offer better immunity to ambient light, temperature variation, and electrical noise, as well as standardized industrial interfaces and factory calibration.

-

Can Arduino-based laser distance sensors be used in industrial applications?

Arduino-based laser distance sensors are suitable for prototyping, education, and early-stage development. However, they are generally not recommended for industrial deployment due to limitations in reliability, environmental resistance, and long-term consistency. Industrial applications usually require certified hardware, stable calibration, and robust communication protocols.

-

When should I move from a prototype laser distance sensor to an industrial solution?

You should consider transitioning to an sensore laser industriale di distanza when field tests show inconsistent results, when the system must operate continuously, or when environmental conditions such as sunlight, temperature changes, or vibration affect performance. Production scaling and customer validation are also strong indicators that an industrial-grade solution is needed.

-

What is an OEM laser distance sensor module, and when is it used?

An OEM laser modulo sensore di distanza is a compact measurement unit designed to be integrated into custom equipment or embedded systems. OEM modules are typically selected after prototype validation, when system requirements are fixed and production planning begins. They offer greater flexibility for mechanical integration and large-scale manufacturing.

-

Are OEM laser distance sensor modules suitable for outdoor applications?

Yes, but only if the OEM module is specifically designed for outdoor use. Outdoor applications require strong resistance to ambient sunlight, weather conditions, and varying target reflectivity. Not all OEM modules are suitable for long-range outdoor measurement, so optical design and signal processing capabilities must be carefully evaluated.

-

What challenges affect long-range laser distance measurement outdoors?

Outdoor long-range measurement is affected by factors such as direct sunlight, rain, fog, dust, and alignment stability over distance. Target surface properties can also influence signal return. Industrial long-range laser distance sensors address these challenges through optical filtering, optimized receiver design, and advanced signal processing.

-

How accurate are industrial laser distance sensors compared to prototype sensors?

Industrial laser distance sensors typically provide more stable and repeatable accuracy over time and temperature ranges. While prototype sensors may achieve good accuracy under controlled conditions, industrial sensors are factory-calibrated and designed to maintain performance in real-world environments.

-

What information should be prepared before requesting an industrial laser distance sensor quotation?

Before requesting a quotation, it is helpful to define the required measurement range, accuracy, operating environment, interface type, and expected production volume. Clear technical requirements allow suppliers to recommend the most suitable industrial or OEM laser distance sensor solution.

-

Can one laser distance sensor solution cover both prototype and production stages?

In some cases, evaluation versions of industrial sensors can be used during late-stage prototyping and then carried into production. However, early prototypes often prioritize flexibility over robustness, so a staged approach—prototype validation followed by industrial or OEM selection—is usually more effective.

-

Why is long-term availability important when selecting an industrial laser distance sensor?

Industrial products often have long lifecycles. Long-term availability ensures consistent performance, stable calibration, and reduced redesign risk over the product’s lifetime. This is especially important for OEM integrations and large-scale deployments.