Selecting the best distance rilevamento technology is a critical step for equipment manufacturers, automation engineers, and OEM designers. Different sensing technologies offer different strengths—accuracy, range, speed, environmental robustness, size, and cost. Understanding these differences ensures that your machine operates reliably and efficiently.

This guide provides a clear, practical comparison of the five most widely used distance detection technologies: sensori laser, Sensori ToF, ultrasonic sensors, sensori a infrarossi, and inductive/capacitive sensors. By the end, you will know exactly which sensing technology fits your application.

Why the Right Distance Detection Sensor Matters

Modern industrial equipment—such as automatic feeders, conveyors, robotic arms, sorting lines, assembly systems, and packaging machines—depends on precise distance data for:

- Object presence detection

- Positioning and alignment

- Height and level measurement

- End-stop control

- Collision prevention

- Quality inspection

- Safe machine operation

Choosing the wrong sensore may cause false triggers, unstable measurement, machine downtime, or production failure. Therefore, selecting the right technology is not just a technical decision—it directly impacts reliability, productivity, and long-term maintenance.

Choosing the Right Distance Detection Technology

Below is a straightforward selection guide that explains when to use each sensing technology and why. This is designed to make decision-making easier for engineers and OEMs.

1. Choose Laser Sensors When You Need High Precision and Long Range

Laser sensors—using triangulation or phase-shift measurement—are the most accurate distance detection technologies available in industrial automation.

Use laser distance sensors when you need:

- High precision (sub-millimeter to millimeter level)

- Long-distance measurement

- Stable performance across reflectivity variations

- Fast response for dynamic movement

- Reliable operation in industrial environments

Ideale per:

- Industrial alignment and positioning

- Robotic calibration

- Long-range material detection

- Height and thickness measurement

- Automated storage and retrieval systems (AS/RS)

If your application involves mechanical accuracy and consistent repeatability, laser sensors are the ideal choice.

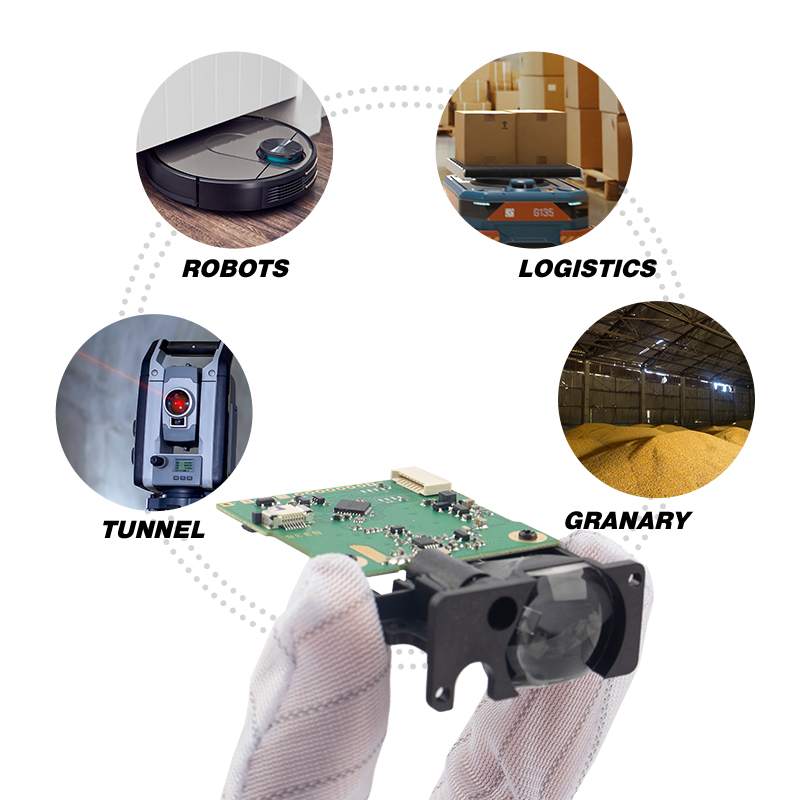

2. Choose ToF Sensors for Fast Response and OEM-Friendly Integration

Tempo di volo (ToF) sensors calculate distance using the travel time of light pulses. Compact, fast, and cost-effective, Sensori ToF are extremely popular in smart machinery and robotics.

Use ToF distance detection sensors when you need:

- Small, lightweight, and easy-to-integrate modules

- Rapid detection for moving objects

- Cost-effective sensing for medium accuracy needs

- Stable performance despite ambient light changes

Ideale per:

- AGVs, AMRs, and service robots

- Obstacle detection and navigation

- Automated feeders and small equipment

- Packaging and sorting machines

- Embedded OEM products

If you need speed, compactness, and integration flexibility, ToF sensors are often the best balance of cost and performance.

3. Choose Ultrasonic Sensors for Transparent or Unpredictable Surfaces

Ultrasonic sensors detect distance using high-frequency sound waves. They perform well regardless of object color, reflectivity, or transparency.

Use ultrasonic sensors when you need:

- Detection of transparent or reflective targets

- Stable performance in dusty, humid, or poorly lit environments

- Reliable mid-range measurement without optical alignment issues

Ideale per:

- Liquid level measurement

- Bottle, glass, or plastic container detection

- Conveyor object presence

- Packaging and filling equipment

If the target surface or environment is challenging for light-based sensors, ultrasonic sensors provide exceptional reliability.

4. Choose IR Sensors for Short-Range, Low-Power Applications

Infrared (IR) sensors use emitted IR light to detect short-range distance.

Use IR distance detection sensors when you need:

- Low-power consumption

- Compact size

- Short-range proximity or misurazione della distanza

- Cost-effective sensing for light industrial or consumer applications

Ideale per:

- Small automation devices

- Compact OEM modules

- Consumer electronics

- Basic object detection

If you need simple, short-range, and economical distance detection, IR sensors are the most lightweight solution.

5. Choose Inductive or Capacitive Sensors for Material-Specific Detection

Inductive sensors detect metal; capacitive sensors detect a wide variety of materials.

Use inductive/capacitive sensors when you need:

- Reliable detection regardless of environmental lighting

- Material-specific sensing (metal, powders, liquids, granules)

- Maintenance-free operation in harsh industrial conditions

Ideale per:

- Metal object verification

- Bottle, grain, or powder level measurement

- Presence detection in sorting or assembly systems

If material type defines your sensing need, inductive or capacitive sensors are the most dependable option.

Distance Detection Technology — comparison of principles, range, accuracy and best use cases

| Tecnologia |

Principio di funzionamento |

Typical Range |

Precisione |

Best Use Cases |

Pro |

Limitations |

| Laser Sensors (Triangulation / Phase-Shift) |

Optical laser emission; distance from triangulation angle or phase difference of returned light. |

Short (triangulation) to long (phase-shift): mm → 100s of m |

Very high (sub-mm to mm) |

Precision alignment, robotic calibration, long-range material detection, thickness/height checks |

Highest precision; long range (phase-shift); fast; stable on many surfaces |

Costlier; may require target reflectivity consideration; alignment for triangulation |

| Sensori a tempo di volo (ToF) |

Emit light pulses (LED/VCSEL or laser); measure round-trip travel time of photons. |

Short to medium (cm → 10s of m) |

Medium (cm → mm depending on model) |

AGV/AMR obstacle detection, embedded OEM modules, fast object presence, mid-range sensing |

Compact; fast response; cost-effective; easy to embed |

Lower ultimate precision than high-end laser phase sensors; performance varies by reflectivity |

| Sensori a ultrasuoni |

Emit ultrasonic sound pulses and measure echo time to calculate distance. |

Short to medium (cm → several meters) |

Medium (cm level) |

Liquid level measurement, transparent or shiny objects, conveyor presence detection |

Unaffected by color/reflectivity; good for liquids/transparent materials; cost-effective |

Slower response; beam spread limits lateral resolution; affected by temperature/airflow |

| Infrared (IR) Sensors |

Emit IR light and measure reflected intensity or simple time delay for short range. |

Very short (mm → 2–3 m) |

Low → Medium (mm → cm) |

Short-range proximity, small automation modules, consumer devices |

Low power; compact; inexpensive |

Sensitive to ambient light; less suitable for long range or highly reflective/translucent targets |

| Inductive Sensors |

Detect metal objects by changes in an electromagnetic field. |

Very short (mm → few cm) |

High for metallic targets (mm level) |

Metal part detection, machine tool presence sensing, safety interlocks |

Extremely robust for metal; unaffected by dust/lighting; long lifetime |

Only detects metal; short range |

| Capacitive Sensors |

Detect changes in capacitance caused by conductive/non-conductive materials. |

Very short (mm → few cm) |

Medium (mm → cm depending on setup) |

Level sensing for powders/liquids, presence of non-metal objects, packaging detection |

Detects a wide range of materials; versatile for level detection |

Requires tuning/calibration; sensitive to humidity and mounting |

| 2D / 3D LiDAR |

Rotating or solid-state laser scanning produces point clouds to map distance over an area. |

Medium → Long (meters → 100s m depending on model) |

High (depends on sensor density and model) |

Mapping, AGV navigation, evitare gli ostacoli, large-area scanning |

Area coverage; high spatial detail; multi-point detection |

Higher cost; heavier processing requirement; may require more power |

How OEMs Can Make the Best Choice

When selecting a distance detection technology, consider:

1. Measurement Requirements

- Distance range

- Precisione

- Risoluzione

- Velocità

2. Condizioni ambientali

- Dust, water, humidity, vibration, lighting

3. Target Material

- Metal, plastic, transparent objects, liquids

4. Integration Requirements

5. Budget and Lifecycle

- Cost-performance ratio

- Maintenance needs

- Expected machine lifespan

Choosing the right technology ensures long-term stability and improved equipment competitiveness.

FAQs About Selecting Distance Detection Technology

-

Do laser and ToF sensors overlap?

They both use light, but laser sensors prioritize precision, while ToF sensors prioritize speed and compactness.

-

Which sensor works best outdoors or in bright light?

Laser sensors and ToF sensors generally handle outdoor light better than IR sensors.

-

What if the target is transparent or shiny?

Ultrasonic sensors perform best in this situation.

-

What if I need extremely high accuracy?

Laser triangulation or phase-shift sensors are the most precise.

-

What if I need to detect metal parts?

Inductive sensors are the most reliable and noise-resistant.

-

Which sensor is best for AGVs and mobile robots?

ToF distance detection sensors provide ideal responsiveness and cost efficiency.

-

Which Distance Detection Technology works best in challenging environments such as dust, vibration, or high humidity?

Ultrasonic technology performs best when the environment contains dust, mist, or transparent materials.

Laser technology offers high precision but may require a clean optical window.

Capacitive sensors work well for powders and liquids but may require sensitivity tuning.

Inductive sensors are extremely robust in metal-detection scenarios.

Choosing the right Distance Detection Technology depends on both the environmental challenge and the material characteristics.

-

What is the most accurate Distance Detection Technology?

The most accurate Distance Detection Technology is laser triangulation or laser phase-shift measurement, which can achieve sub-millimeter or millimeter-level accuracy. Industrial-grade laser sensors outperform ToF, ultrasonic, and infrared technologies when extreme accuracy is required.

-

Which Distance Detection Technology is best for long-range measurement?

For long-range applications such as outdoor monitoring, AGV navigation, warehouse logistica, or structural inspection, laser phase-shift sensors or LiDAR technologies are the best choices. They provide long-distance measurement capabilities while maintaining stable accuracy.

-

How does Distance Detection Technology improve automation safety?

Distance Detection Technology allows machines to perceive obstacles, detect presence, maintain alignment, and trigger emergency stops when required. AGVs, robotic arms, conveyor systems, and packaging machines rely on distance detection to avoid collisions, maintain controlled motion, and ensure safe operation around people.

-

What are the most cost-effective Distance Detection Technologies for OEM applications?

For cost-sensitive products with compact space:

Sensori ToF are the most popular due to their small size, fast response, and competitive pricing.

Infrared distance sensors provide affordable short-range detection.

Ultrasonic sensors offer good performance at moderate cost for general detection tasks.

The ideal Distance Detection Technology depends on range, speed, accuracy, and target material.

-

Which Distance Detection Technology is best for small OEM devices or embedded modules?

Sensori ToF are the top choice thanks to their compact size, simple electrical interface, low power consumption, and fast update rate. Many miniaturized robotics, consumer devices, and embedded automation systems rely on ToF-based Distance Detection Technology.

-

What Distance Detection Technology is best for UAV gimbals and aerial inspection pods?

For UAV gimbals, aerial inspection pods, and airborne measurement tasks, the most suitable Distance Detection Technology is laser-based phase-shift or ToF technology.

Distanza laser Detection Technology provides long-range accuracy required for altitude estimation and object inspection.

Sensori ToF offer lightweight costruzione, low power consumption, and fast response—ideal for stabilizing gimbals during flight.

This combination ensures stable positioning, obstacle detection, and precise ground distance measurement under varying light conditions.

-

What Distance Detection Technology is best for robotic arms in industrial automation?

Robotic arms require fast, reliable, and repeatable positioning.

The best Distance Detection Technology for this scenario is laser triangulation or high-speed ToF sensors:

Laser triangulation ensures sub-millimeter accuracy for gripping, alignment, and pick-and-place workflows.

ToF technology offers rapid distance feedback for adaptive motion, safe movement, and dynamic obstacle detection.

Combining both improves robotic precision and environment awareness.

-

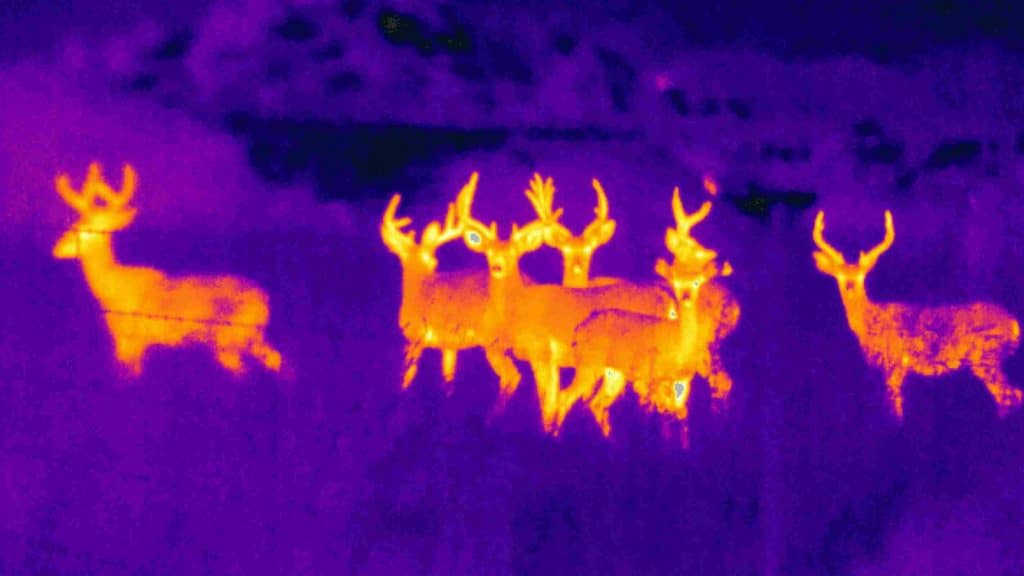

What Distance Detection Technology is best for thermal imaging systems or dual-sensor platforms?

Thermal imaging alone cannot provide depth information, so integrating Distance Detection Technology is essential.

The best choices are:

Laser Distance Detection Technology, which provides precise range data to fuse with thermal images

ToF modules, which add compact 3D sensing without interfering with IR wavelengths

These technologies enable temperature-plus-distance analysis, target size estimation, and more accurate anomaly detection in industrial inspections.

-

What Distance Detection Technology is best for intelligent storage and inventory monitoring?

For stock level measurement, pallet detection, or warehouse volume monitoring, the ideal Distance Detection Technology is:

Laser phase-shift sensors for long-range accuracy in high-bay racking

Sensori ToF for rapid detection of box presence and package height

Ultrasonic Distance Detection Technology for detecting liquids or irregular materials in silos

Laser and ToF are particularly effective for real-time warehouse automation, height detection, and carton scanning systems.

-

What Distance Detection Technology is best for conveyor belts and packaging machines?

Industrial conveyors need high-speed sensors that can detect passing objects, position items, and measure height.

The recommended Distance Detection Technologies include:

Laser triangulation for high-speed part detection and alignment

Sensori ToF for presence verification and short-range distance measurement

Capacitive or inductive sensors when detecting specific materials (e.g., metal, plastic, powder)

These options ensure stable detection even in dusty or high-vibration environments.

-

What Distance Detection Technology is best for precision alignment and machine calibration?

For machine tool alignment, CNC calibration, and precision fixture positioning:

Laser triangulation sensors offer the highest accuracy and repeatability

High-resolution ToF Distance Detection Technology provides fast feedback for dynamic alignment

Laser-based solutions remain the gold standard when reliability and precision are critical.

-

What Distance Detection Technology is best for mobile robots and autonomous navigation?

Autonomous robots, AGVs, and AMRs need robust Distance Detection Technology that functions reliably in warehouses, corridors, and dynamic environments.

The best technologies include:

Misurazione laser della distanza (LiDAR or phase-shift) for mapping and long-range navigation

ToF for short-range obstacle detection

Ultrasonic sensors for detecting transparent or irregular surfaces

Together, these Distance Detection Technologies support collision avoidance, path planning, and real-time localization.

https://meskernel.net/laser-measure/