When OEM buyers evaluate a 레이저 측정 module for embedded systems, industrial equipment, or robotics projects, the selection process often starts—and ends—with technical specifications such as range and accuracy.

However, real-world OEM projects frequently encounter integration issues not because the sensor lacks performance, but because critical integration factors were overlooked early in the selection stage.

In OEM and embedded applications, a laser measurement module refers to a compact laser-based 거리 측정 unit designed for direct system integration rather than standalone use.

This article highlights the most common mistakes OEM buyers make when choosing a laser measurement module—and how to avoid them.

Understanding OEM Application Requirements Beyond Specifications

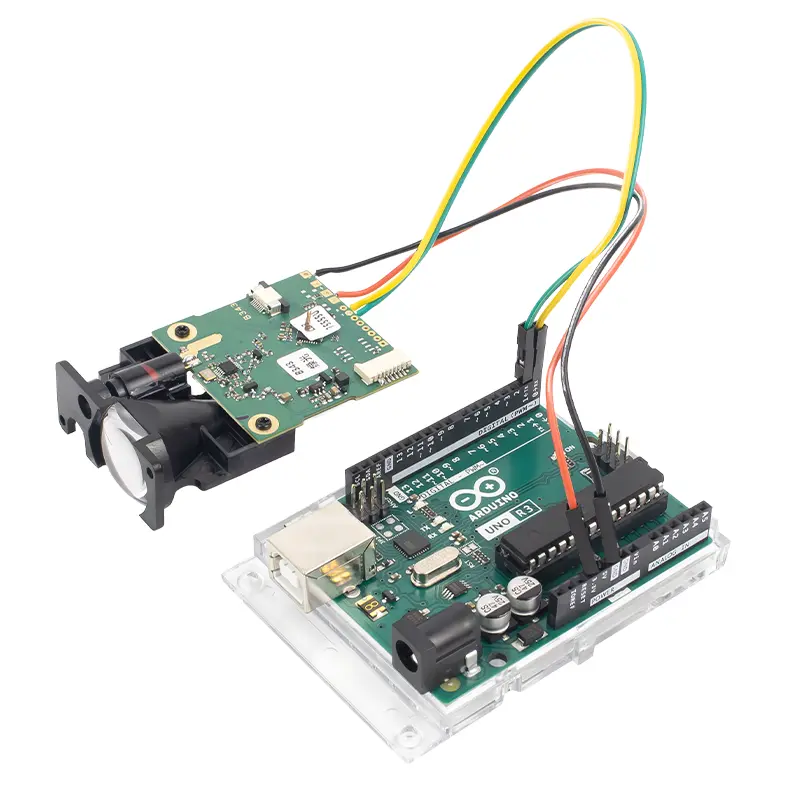

A 레이저 측정 센서 module is rarely used as a standalone device in OEM projects. Instead, it is embedded into a larger system, where it must work reliably with controllers, firmware, power supplies, and mechanical structures.

Before comparing specifications, OEM teams should clarify:

- How will the module be integrated into the system?

- Which controller or processor will it communicate with?

- What is the required measurement update rate?

- Will the module operate continuously or intermittently?

Skipping this step often leads to selecting a module that looks suitable on paper but creates challenges during integration.

Common Pitfall: Comparing Only Range and Accuracy

One of the most frequent mistakes OEM buyers make is evaluating a laser measurement module purely based on:

- Maximum measurement range

- Nominal accuracy or resolution

While these parameters matter, they rarely determine integration success.

For example, a module with excellent accuracy may still be unsuitable if it lacks compatible communication interfaces or cannot meet system timing requirements. In OEM environments, data accessibility and system compatibility are just as important as 광학 performance.

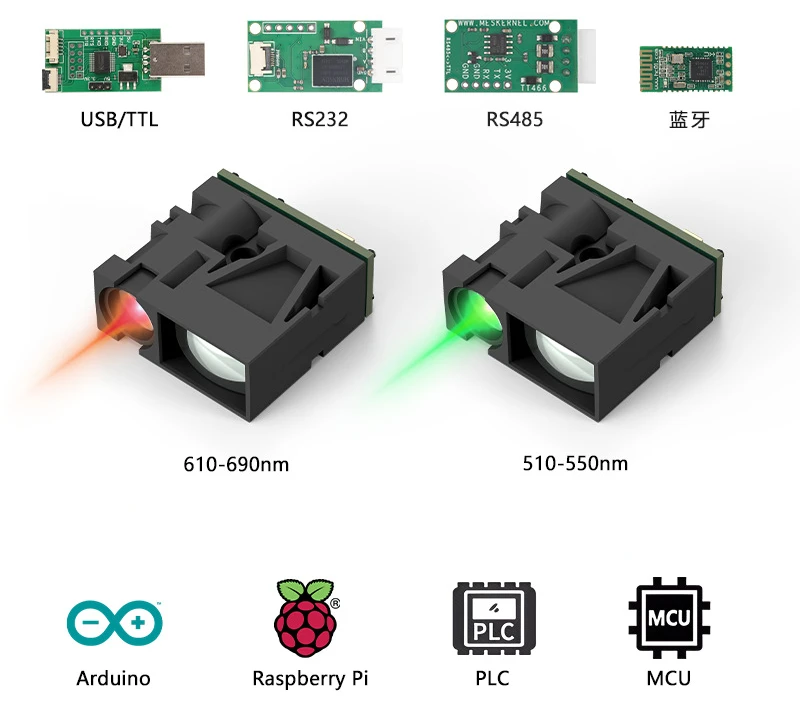

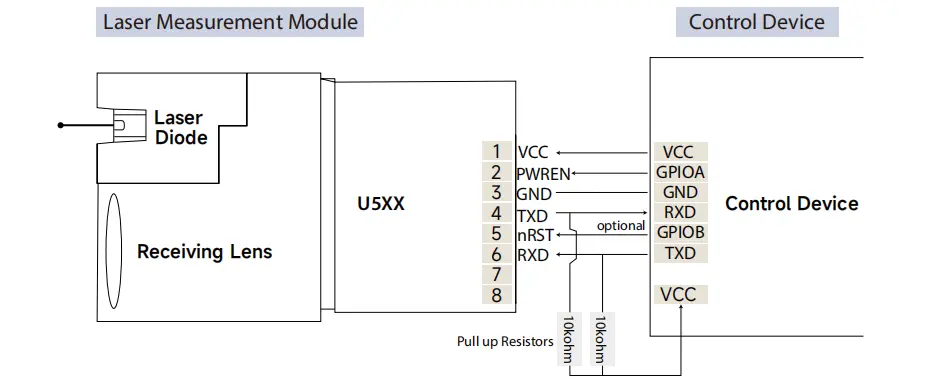

Why Communication Interfaces Matter More Than Expected

Communication interfaces are often underestimated during early selection, yet they directly affect development time and system stability.

선택할 때 레이저 거리 센서 module, OEM buyers should verify support for interfaces such as:

- UART / TTL for microcontroller-based systems

- RS232 or RS485 for industrial controllers and PLC environments

- Protocol flexibility to match existing firmware architecture

Selecting a module without the right interface may require additional converters or redesigns, increasing cost and delaying project timelines.

For OEM integration, interface compatibility should be considered a core requirement, not an afterthought.

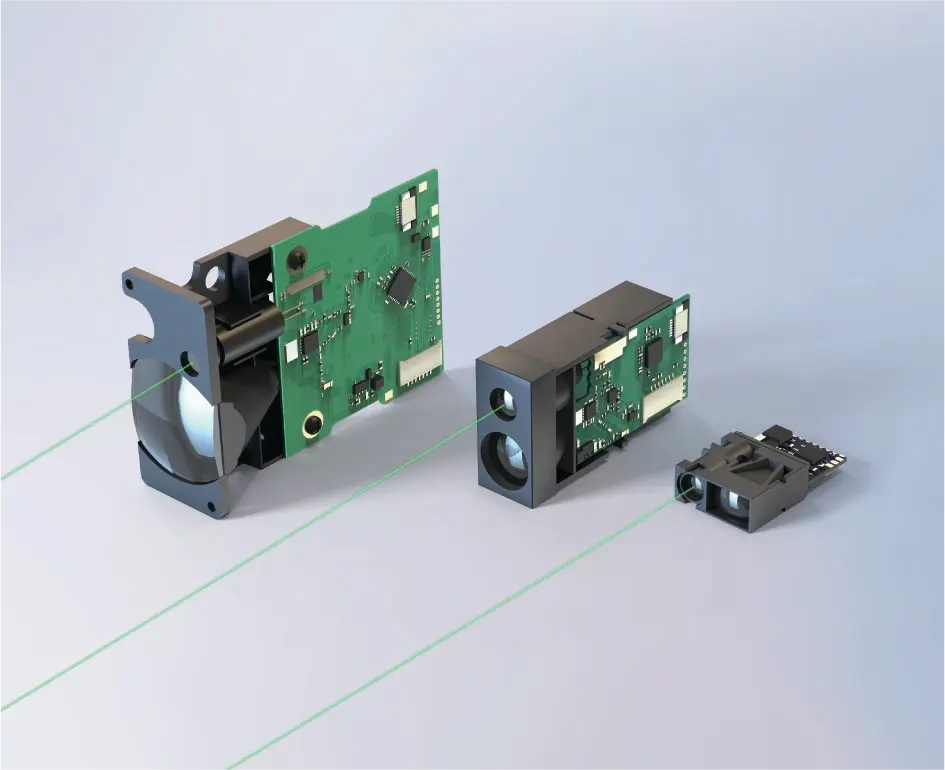

Module Packaging and Mechanical Integration Considerations

Another overlooked aspect is physical packaging.

OEM products often have strict space constraints, and the laser measurement module must fit within:

- Limited mechanical envelopes

- Custom housings or enclosures

- Environments with vibration, dust, or temperature variations

A compact module with flexible mounting options can significantly simplify mechanical design. In contrast, choosing a module without considering packaging may result in last-minute mechanical revisions.

Why Customization Capability Is Critical for OEM Projects

Standard, off-the-shelf modules may work for evaluation—but OEM projects rarely remain standard.

Common customization requirements include:

- Modified communication protocols

- Custom baud rates or data output formats

- Adjusted measurement ranges or response behavior

- Application-specific calibration

OEM buyers should assess whether the supplier of a laser measurement module offers engineering-level customization support, not just standard products. Early confirmation of customization capability can prevent redesigns later in the project lifecycle.

OEM Buyer Checklist for Laser Measurement Module Selection

Before finalizing a sensor supplier, OEM buyers should confirm the following:

- ✅ Measurement range and accuracy match real application needs

- ✅ Communication interface aligns with system architecture

- ✅ Module size and packaging fit mechanical constraints

- ✅ Environmental suitability meets operating conditions

- ✅ Customization and engineering support are available

Using this checklist helps reduce integration risks and ensures smoother product development.

Choosing a Laser Measurement Module with Integration in Mind

In OEM applications, the success of a laser measurement module is not defined by specifications alone. Integration compatibility, interface flexibility, packaging, and customization support all play a decisive role.

By evaluating laser measurement modules from a system integration perspective, OEM buyers can avoid common pitfalls, reduce development cycles, and build more reliable end products.

Frequently Asked Questions About Laser Measurement Modules

-

What is a laser measurement module used for in OEM applications?

A laser measurement module is commonly used in OEM systems to provide non-contact distance measurement for industrial equipment, robotics, automation systems, and embedded applications. OEM buyers typically integrate the module directly into their product architecture rather than using it as a standalone device.

-

How is a laser measurement module different from a finished laser distance sensor?

A laser measurement module is designed for system integration and OEM use, often without a full enclosure or display. Compared to finished 레이저 거리 sensors, modules offer greater flexibility in packaging, communication interfaces, and customization for embedded applications.

-

Which communication interfaces are most common for laser measurement modules?

Common communication interfaces for laser measurement modules include UART/TTL for microcontroller-based systems and RS232 or RS485 for industrial controllers and PLC environments. Choosing the right interface is critical for smooth system integration.

-

What should OEM buyers prioritize besides range and accuracy?

In addition to range and accuracy, OEM buyers should prioritize interface compatibility, mechanical packaging, environmental suitability, and customization capability when selecting a laser measurement module. These factors often determine real-world integration success.

-

Can laser measurement modules be customized for specific OEM projects?

Yes. Many OEM projects require customization such as modified communication protocols, custom baud rates, or application-specific calibration. Confirming customization capability early helps reduce development risks and project delays.

-

Are laser measurement modules suitable for harsh industrial environments?

Laser measurement modules can be designed for industrial environments, but suitability depends on factors such as operating temperature, vibration resistance, and enclosure integration. OEM buyers should verify environmental specifications during the selection process.

https://meskernel.net/oem-laser-distance-sensor/

https://meskernel.net/laser-distance-measurer-sensor/

https://meskernel.net/laser-distance-sensor-errors/