When searching for sensor for pomiar odległości, laser, ultrasonic, and infrared options dominate the market. But which one best suits your needs? This comprehensive guide will help you make an informed choice by diving into technologies, performance metrics, and real-world use cases.

🔍 1. Sensor Types at a Glance

| Typ czujnika | Zasięg | Dokładność | Plusy | Cons |

|---|

| Laser (ToF/Phase) | Short (<200 m) to very long (>1 km) | ±1 mm (phase), ±cm (ToF) | High precision, long distance, fast | More expensive, requires eye safety, surface sensitivity |

| Ultradźwiękowy | Up to ~10 m | ±1–3 cm | Affordable, works in darkness | Limited range, wide beam, affected by air conditions |

| Podczerwień | Short (<5 m) | ±1–5 cm | Compact, low-cost proximity sensing | Poor accuracy, limited range |

Czujniki laserowe, especially those for industrial use, stand out when precision and distance matter. Meskernel’s industrial odległość lasera sensors offer ±1 mm accuracy and ranges from centimeters to kilometers, with versatile UART/RS232/RS485 connectivity .

2. Key Performance Parameters

- Dokładność pomiaru & Resolution

- Phase‑shift sensors achieve ±1 mm accuracy at short and mid ranges.

- Czujniki ToF suit longer distances with ±2–5 cm accuracy.

- Range & Speed

- Environmental Robustness

- Interface & Integration

- Connectivity options include UART, TTL, USB, RS‑232/485, CAN, Bluetooth, and Modbus.

- Ensure compatibility with control systems like PLCs, Raspberry Pi, or Arduino.

3. Applications by Industry

🚗 AGVs & Robotics

Reliable navigation relies on sub-millimeter precision and fast update rates.

Recommend: LDL‑20-20 Hz, LDL‑S, or compact industrial sensors with IP67 protection.

📏 Surveying & Mapping

Applications like topography demand both range and precision.

Recommend: Meskernel’s long-range sensors (up to 5000 m).

🏭 Warehouse / Logistics

Forklift or drone scanning needs mid-range (20–100 m), good accuracy, and ruggedness.

Recommend: Industrial high‑frequency or IP-rated sensors, or 3D ToF LiDAR moduły.

4. Laser vs. Infrared vs. Ultrasonic

- Laser: Best for precise, long-range, rapid measurements.

- Ultradźwiękowy: Budget-friendly, but limited precision and range.

- Podczerwień: Simple and compact, best for proximity wykrywanie.

5. Meskernel Sensor Comparison Table

| Model | Type | Zasięg | Dokładność | Częstotliwość | Interfejs | Ruggedness |

|---|

| 1 mm LDL‑S | Phase / ToF | 0.1–30 m | ±1 mm | 30 Hz | TTL / RS232 / RS485 / BT | Outdoor / Sunlight |

| LDJ‑200 | Phase | 0.03–200 m | ±1 mm | 20 Hz | UART, USB | Compact |

| TC25 / 1000 m sensor | Pulse Ranging | Up to 1000 m | ±1 m | N/A | TTL | Ritual-use |

| LDL‑20-20 Hz | Phase | 0.03–20 m | ±1 mm | 20 Hz | UART / RS‑232/485 | Rugged |

| Long‑Range 1000 m model | Pulse | Up to 1000 m | ±1 m | N/A | UART | Przemysłowy |

These models span from compact, sun-optimized units to long-range industrial-grade modules.

6. Integration Tips & Buying Checklist

- Define Your Needs: Clarify range, accuracy, frequency, environment.

- Choose the Right Tech: For mm-precision and distance: prioritize laser phase/ToF.

- Check Interfaces: Match with your system.

- Look for Ruggedness: Outdoor or dusty conditions demand IP rating.

- Review Support & Customization: Meskernel offers OEM/ODM services.

- Validate Certification: Check laser safety class (Class 1/2).

Product Recommendation

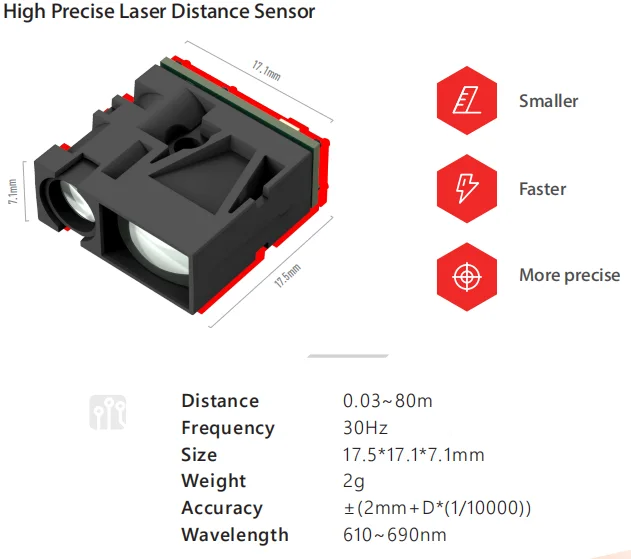

Czujnik wykrywania odległości Tof

Czujnik wykrywania odległości Tof

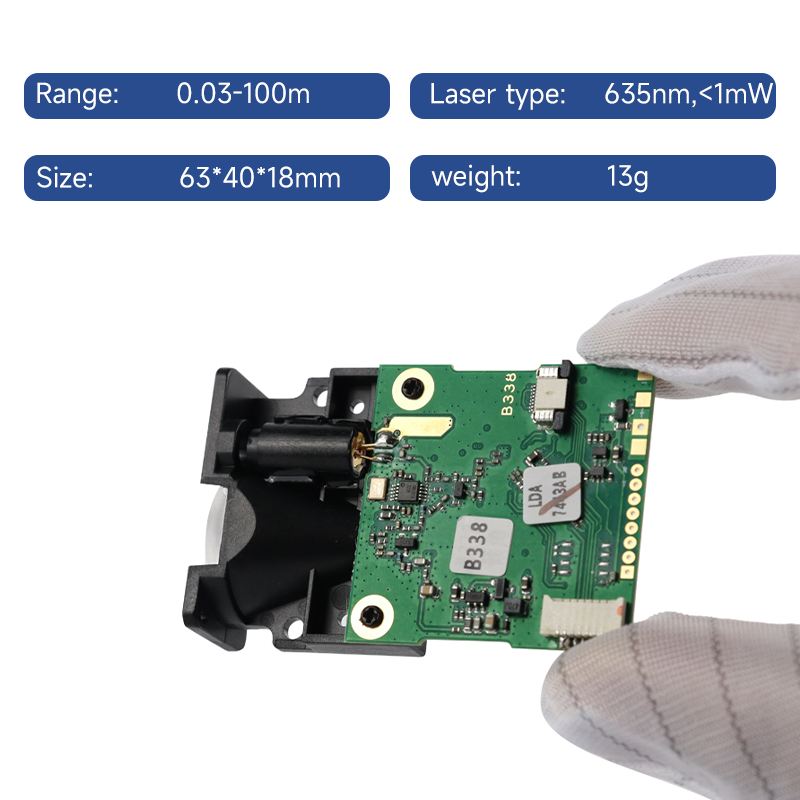

czujnik odległości analogowy wyjście

czujnik odległości analogowy wyjście

Final Takeaway

For serious buyers seeking distance measurement sensors, laser-based systems deliver unmatched precision, range, and speed. From indoor robotics to outdoor pomiary and warehouse automation, Meskernel’s variety—from mm-resolution to km-range, and sun-resistant to IP-rated modules—makes them an ideal partner.

📌 Frequently Asked Questions (FAQs) About Sensor for Distance Measurement

-

What is the best sensor for distance measurement?

The best sensor for distance measurement depends on your application. Laserowe czujniki odległości offer the highest accuracy (±1 mm) and are ideal for long-range and industrial use. Ultrasonic sensors are better for short-range, budget-friendly applications, while czujniki podczerwieni work well for basic proximity detection.

-

How accurate are laser sensors for distance measurement?

Laser sensor for distance measurement can achieve sub-millimeter accuracy. For example, Meskernel’s phase-based laser sensors provide up to ±1 mm precision, making them suitable for precision engineering, industrial automation, and robotic positioning.

-

What’s the difference between ultrasonic, infrared, and laser sensors for measuring distance?

Czujniki laserowe: High precision, long range, fast response.

Czujniki ultradźwiękowe: Moderate accuracy, short range, low cost.

Czujniki podczerwieni: Compact and affordable, but limited in range and accuracy.

Each sensor for distance measurement has trade-offs in range, environment adaptability, and measurement frequency.

-

Can I use a laser sensor for outdoor distance measurement?

Yes, many laser sensor for distance measurement are optimized for outdoor environments. For example, the LDL-S model from Meskernel is designed to operate in strong sunlight and achieve reliable readings up to 30 m outdoors with ±1 mm accuracy.

-

Which distance measurement sensor works best for AGVs or warehouse automation?

For AGVs, forklifts, or robotic arms, you need a sensor for distance measurement that is both accurate and fast. High-frequency laser sensors like the LDL-20-20 Hz offer reliable performance in dynamic, industrial settings with sub-millimeter precision.

-

What communication interfaces do distance measurement sensors support?

Many modern distance measurement sensors support TTL, UART, RS‑232, RS‑485, CAN, USB, Modbus, and even Bluetooth. Meskernel offers sensors with multiple interface options to ensure seamless integration with your existing control systems.

-

How do I choose the right sensor for distance measurement?

To select the right sensor for distance measurement, consider:

1.Required range and accuracy

2.Operating environment (indoor/outdoor)

3.Object surface characteristics

4.Measurement speed

5.Integration requirements (interface, protocol)