Optical Sensor for Water or Liquid Level: A Smart Solution for Monitoring Fluid Levels

Monitoring liquid levels is a critical task in various industries, from water treatment plants to chemical processing and even home appliances like fish tanks and water dispensers. Traditional methods, such as mechanical float sensors or pressure sensors, have their limitations in terms of reliability, accuracy, and ease of maintenance. In contrast, optical sensors offer a non-contact, precise, and reliable solution for measuring water or liquid levels. In this blog post, we will explore how optical sensors work for liquid level detection and why they are an excellent choice for a wide range of applications.

Key Features:

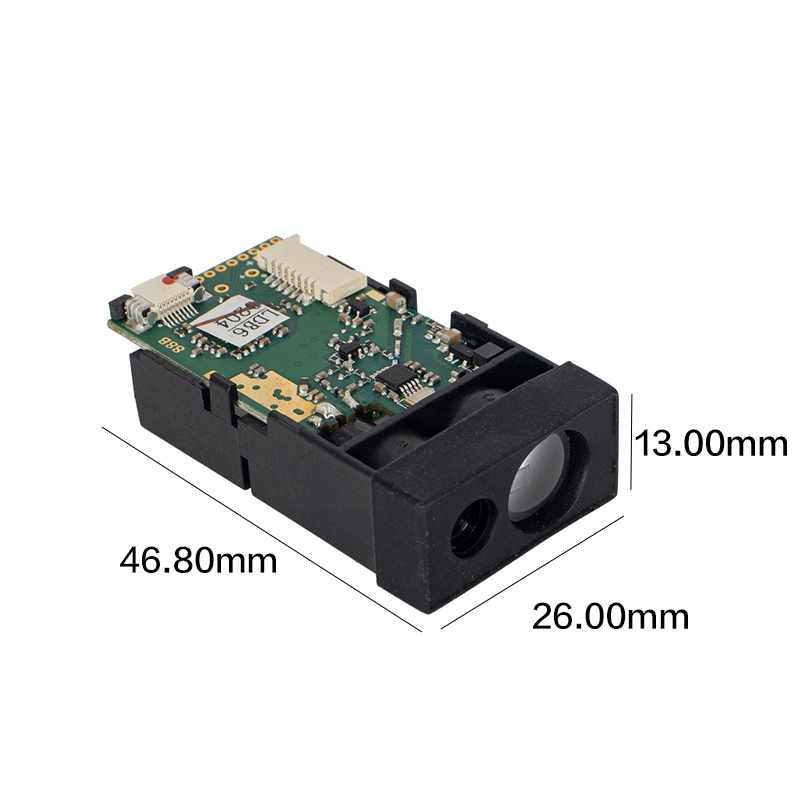

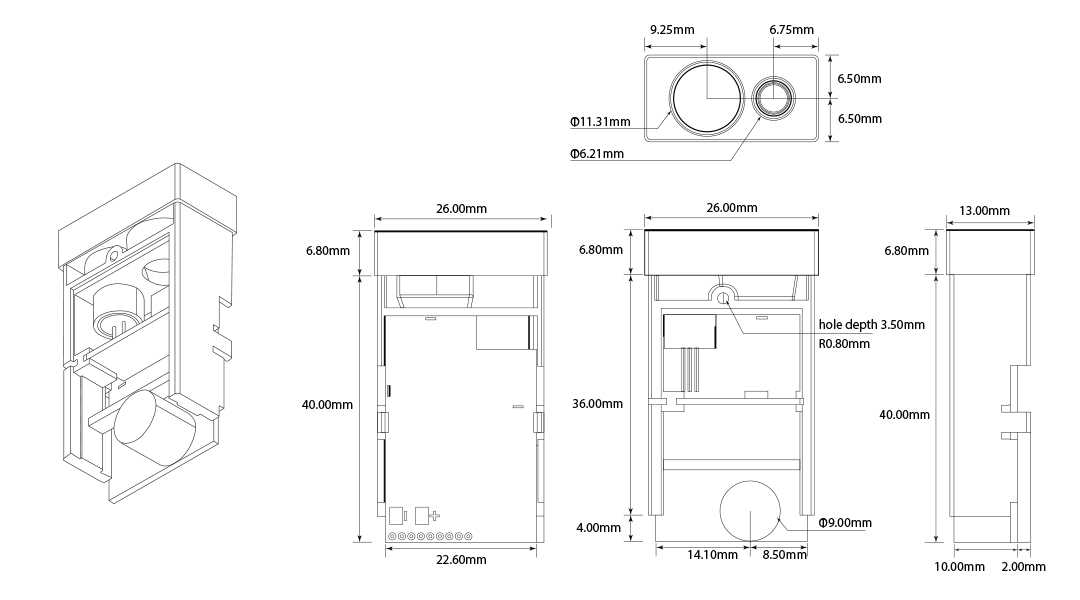

- Ultra-High Precision: Achieve unparalleled measurement accuracy with a tolerance of just ±0.01 meters, ensuring you get precise data every time, whether for short-range or long-distance measurements.

- Wide Measurement Range: The sensor operates effectively over a wide range from 0.03 meters to 60 meters, making it versatile enough for applications ranging from small-scale projects to large industrial setups.

- USB Interface: The USB connectivity ensures easy integration with various devices, such as PCs, microcontrollers, and data loggers. No need for complex installations—simply plug and play.

- Fast Response Time: With a rapid response time, this sensor is perfect for real-time distance monitoring and control systems, minimizing lag in dynamic environments.

- Durable and Reliable: Built to withstand harsh environments, this sensor is designed for longevity and consistent performance in various industrial and commercial applications.

- Easy to Use: Equipped with a user-friendly USB interface, setup and operation are simple, making it accessible for both experienced professionals and DIY enthusiasts.

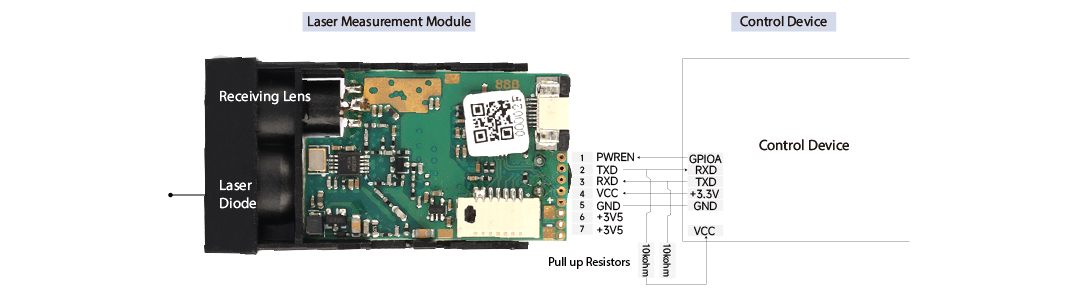

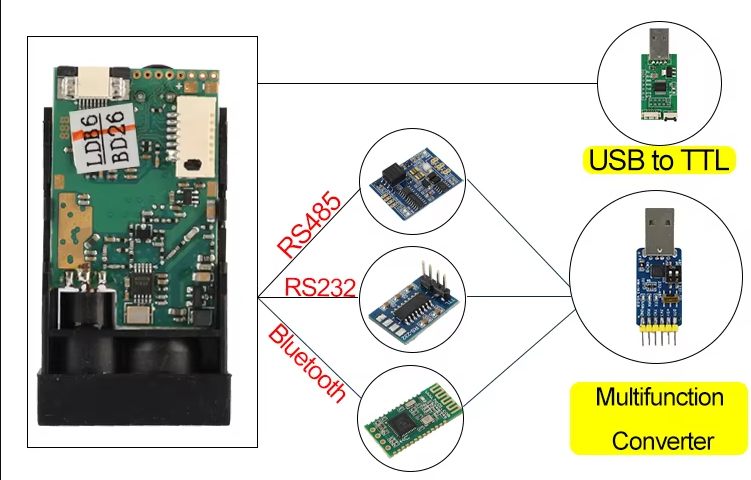

Communication Port:

Applications of Optical Sensors for Liquid Level Monitoring

- Measuring Different Surface:Measuring dark, glossy, or high reflective surfaces like red liquid aluminum solution, or molten steel.

- Outdoor Measurement:Green laser beam has better visibility, and stronger measuring ability under sunlight.

- Underwater Detection:Penetrating the water to get the measuring data.

- Water Treatment Plants:In water treatment facilities, optical sensors are used to monitor the level of water in tanks, reservoirs, and piping systems. They help ensure that water levels remain within safe ranges, optimizing the treatment process and preventing overflow or underflow conditions.

- Chemical Processing:In chemical processing plants, optical sensors can monitor the levels of various liquids in reaction vessels, tanks, and storage containers. The precise measurement capabilities help ensure that chemical reactions occur at the correct rates and help avoid potential hazards related to overflows or chemical spills.

- Food and Beverage Industry:In the food and beverage industry, optical sensors are employed to monitor liquid levels in tanks, mixers, and packaging machines. They help improve efficiency, prevent overflows, and ensure consistent quality control.

- Consumer Electronics and Appliances:Optical sensors are used in various consumer electronics, such as water dispensers, coffee machines, and fish tanks, to monitor liquid levels. These sensors are ideal for appliances that require compact, non-invasive, and reliable liquid detection.

- Pharmaceutical Industry:In the pharmaceutical industry, optical sensors help monitor the liquid levels in mixing tanks, storage vats, and dispensing machines. The precision of optical sensors ensures accurate production and dispensing of liquids in controlled environments.

1. How Optical Sensors Work for Liquid Level Detection

An optical sensor for liquid level detection uses light (usually infrared or visible) to detect the presence or absence of a liquid at a specific level. These sensors work on the principle of refraction, reflection, or transmission of light. Depending on the design, the sensor can detect whether the liquid is above or below a certain threshold.

Here are the basic components and working principles of optical liquid level sensors:

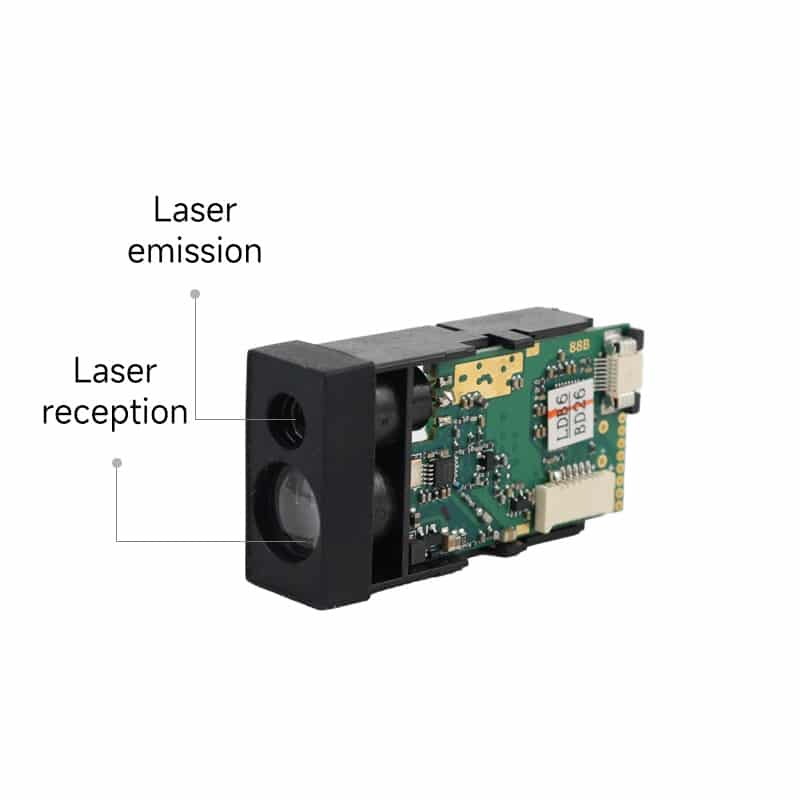

- Light Source: The sensor uses an LED or laser light as a source. This light is directed towards the surface where the liquid level is being monitored.

- Receiver/Photodetector: A photodiode or phototransistor receives the reflected or refracted light. The amount and angle of light that the sensor detects can indicate the presence or absence of liquid.

- Detection Mechanism:

- When the liquid is present, it either reflects or refracts the light in a way that the sensor can measure.

- When the liquid is absent, light is either fully reflected or passes through an air gap, triggering the sensor to indicate that the tank or container is empty.

This method of liquid detection is highly reliable and avoids the mechanical wear and tear associated with traditional sensors.

2. Types of Optical Sensors for Liquid Level Detection

Optical sensors come in various types, each suited for different applications and liquid characteristics. Below are the most common types used for water or liquid level detection:

- Optical Through-Beam Sensors: This type of sensor has a light emitter and a separate receiver, placed on opposite sides of the container. When the liquid reaches the sensor, it interrupts the light beam, causing the sensor to detect the liquid level.

- Optical Reflective Sensors: In these sensors, the light emitter and receiver are combined into a single unit, typically placed on the side of the container. The sensor detects changes in light reflection when the liquid reaches the sensor, providing level detection.

- Capacitive Optical Sensors: These sensors use the refractive index of the liquid to detect the liquid level. They can measure the level of both transparent and opaque liquids, making them versatile for various applications.

- Fiber Optic Liquid Level Sensors: These sensors use fiber optics to transmit light and detect changes in light patterns as the liquid level fluctuates. They are particularly useful for harsh or hazardous environments where non-contact measurements are necessary.

3. Advantages of Using Optical Sensors for Liquid Level Detection

Optical sensors offer several advantages over traditional liquid level detection methods:

- Non-contact Measurement: Since optical sensors don’t require physical contact with the liquid, they eliminate the issues associated with mechanical wear and corrosion, ensuring a longer lifespan.

- High Accuracy and Sensitivity: Optical sensors can detect small changes in liquid levels, making them ideal for applications requiring precise measurements. They offer superior accuracy compared to float-based or pressure-based sensors.

- No Moving Parts: Optical sensors have no moving parts, reducing the risk of mechanical failure and increasing reliability. This is particularly important in harsh environments where wear and tear are a concern.

- Quick Response Time: Optical sensors can provide immediate feedback, making them ideal for real-time monitoring of liquid levels in fast-changing environments.

- Versatile Applications: Optical sensors can work with a wide range of liquids, including water, oil, chemicals, and even some viscous fluids, depending on the sensor type. They are ideal for applications where non-invasive and precise monitoring is crucial.

Why Choose This Optical Distance Sensor?

This Optical Distance Sensor stands out because of its accuracy, flexibility, and ease of integration. Whether you’re looking to measure the distance of objects in real-time for automation, robotics, or consumer electronics, this sensor delivers with high precision and quick response times. Its USB interface allows for seamless connection with a variety of devices, making it one of the most user-friendly solutions on the market.

Optical sensors for water or liquid level detection provide a reliable, accurate, and non-contact solution for a wide range of industries. Their high precision, ease of maintenance, and versatility make them an excellent choice for applications where traditional sensors might fall short. Whether you’re working in water treatment, automotive, food processing, or consumer electronics, optical liquid level sensors can help optimize processes, improve safety, and enhance efficiency. As technology advances, these sensors will continue to play an essential role in automated monitoring systems across various sectors.

If you’re considering an optical sensor for your liquid level monitoring needs, be sure to choose one that fits your specific application and environmental conditions for optimal performance.