When comparing laser distance sensor technologies, ToF vs Triangulation is a common debate. Both Time-of-Flight (ToF) and Triangulation methods offer high-precision distance measurement, but they operate in distinctly different ways. In this article, we’ll explore these two technologies in detail, highlight their respective advantages, and help you determine which method is best suited for your specific needs—especially if you’re looking to integrate a laser distance sensor into your projects. Whether you need high accuracy, long-range measurements, or adaptability to various environments, understanding the differences between ToF and Triangulation will be crucial in selecting the right solution.

Understanding Time-of-Flight (ToF) Technology

Time-of-Flight (ToF) technology uses the speed of light to measure distances. It works by emitting a laser pulse, measuring the time it takes for the light to travel to the target and back, and then calculating the distance based on that time. When comparing ToF vs Triangulation, ToF excels in providing accurate, long-range measurements, making it ideal for projects requiring fast and reliable distance sensing. In contrast, triangulation offers high precision in closer, more confined spaces. Understanding the differences between these two technologies helps in choosing the right laser distance sensor for your application.

Key Advantages of ToF:

- Long Range: ToF sensors can measure distances over long ranges, often up to several hundred meters or more, making them ideal for applications in outdoor environments and large-scale industrial setups.

- High Precision: ToF technology offers high accuracy, making it suitable for precision-based applications like autonomous vehicles, drones, and surveying.

- Simple Operation: Since ToF relies on a single pulse and a time measurement, it has a relatively simple setup compared to other technologies.

- Speed: ToF sensors provide fast measurements, with minimal lag, which is crucial for real-time applications like obstacle detection in drones or robots.

Applications of ToF Laser Distance Sensors:

- Drones: For altitude measurements and obstacle avoidance.

- Industrial Automation: For precise distance control and monitoring.

- 3D Mapping: Used in LIDAR systems for topographic surveys.

How Triangulation Works

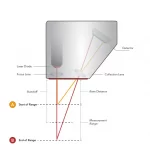

When comparing ToF vs Triangulation, it’s important to understand how each method operates. Triangulation uses geometric principles to calculate distances. It works by projecting a laser point onto the target and measuring the angle of the reflected light relative to a fixed reference. Using this angle and the known baseline distance between the emitter and the sensor, triangulation algorithms accurately compute the distance. While ToF is better suited for long-range, real-time applications, Triangulation excels in delivering high precision at shorter ranges, especially in controlled environments.

Key Advantages of Triangulation:

- Accuracy at Shorter Distances: Triangulation excels in measuring distances at shorter ranges, providing extremely high precision in confined or smaller environments.

- Resolution: Triangulation-based sensors typically offer higher resolution compared to ToF sensors, making them ideal for applications requiring detailed, fine measurements.

- Compact Design: Since triangulation sensors rely on optical systems to measure angles, they tend to be more compact and can be integrated into smaller devices.

Applications of Triangulation Laser Distance Sensors:

- Robot Localization: For high-precision mapping and pathfinding in confined spaces.

- Industrial Measurement: Used in manufacturing for precise inspection and quality control.

- Consumer Electronics: Found in applications like gesture recognition and proximity sensors.

ToF vs Triangulation: Which Technology is Best for Your Needs?

1. Range and Distance

If your project requires measuring distances over hundreds of meters, ToF technology is the obvious choice. It’s ideal for applications like drones, aerial mapping, and large-scale industrial setups. However, if you only need to measure distances in a small area with high precision, triangulation might be more suitable, especially for applications like robotics and product inspection.

2. Accuracy vs Resolution

Triangulation typically offers better resolution and higher accuracy at short distances, while ToF provides reliable measurements over long ranges with acceptable accuracy. If your project involves measuring precise distances in a small-scale environment, go for triangulation. But for larger, more dynamic environments, ToF technology shines.

3. Speed and Real-Time Data

When comparing ToF vs Triangulation, one key difference lies in speed and responsiveness. ToF sensors are significantly faster at delivering real-time distance data, making them ideal for applications that demand continuous measurement and immediate adjustments—such as robotics, drones, and automation systems. In contrast, while triangulation offers high precision, it can be slower in response, making it less suitable for real-time applications where rapid distance updates are critical. Understanding this trade-off is essential when choosing the right laser distance sensor for your specific use case.

Choosing the Right Laser Distance Sensor for Your Application

When selecting between ToF vs triangulation, it’s essential to assess the nature of your project. Consider the following factors:

- Measurement Range: For long-range applications, ToF is your best bet.

- Precision: For small-scale, high-accuracy measurements, triangulation is superior.

- Real-time Operation: For fast, real-time feedback, ToF sensors are the go-to solution.

- Environment: For outdoor and large-scale environments, ToF sensors perform better, while triangulation excels in controlled indoor spaces.

measure distance

measure distance Laser Sensor TS1224

Laser Sensor TS1224 Laser Distance Measurement Sensor LDK

Laser Distance Measurement Sensor LDK range finder

range finder laser measure

laser measure Distance Measurement Sensor

Distance Measurement SensorFrequently Asked Questions (FAQs)

Q1: What is the main difference between ToF vs triangulation technologies?

The primary difference lies in how the distance is measured: ToF measures the time it takes for light to travel to a target and back, while triangulation calculates the distance based on angles formed by the sensor, target, and reference point.

Q2: Which technology offers better accuracy?

In the ToF vs Triangulation comparison, accuracy varies depending on the measurement range. At short distances, Triangulation typically delivers better accuracy thanks to its higher resolution and precise angle detection. In contrast, Time-of-Flight (ToF) maintains reliable accuracy over longer ranges, making it a better choice for large-scale applications such as drone navigation, warehouse automation, and outdoor measurement tasks. Understanding these strengths helps in selecting the most suitable laser distance sensor for your specific needs.

Q3: Can both technologies be used in LIDAR systems?

Yes, both ToF vs triangulation are used in LIDAR systems. ToF is more common in long-range LIDAR applications like autonomous vehicles and drones, while triangulation is used in close-range scanning systems, such as indoor robots.

Q4: How do I choose between ToF vs triangulation for my drone project?

For drone applications, ToF sensors are typically preferred because they can measure distances over longer ranges, which is essential for altitude measurement and obstacle detection in real-time.

Q5: Can I integrate these technologies with my Raspberry Pi?

Yes, both ToF vs triangulation-based laser distance sensors can be integrated with a Raspberry Pi using interfaces like I2C or UART, allowing for real-time data collection and analysis.

Conclusion

Both ToF vs triangulation technologies offer distinct advantages depending on your project’s specific needs. ToF sensors excel in long-range applications and fast measurements, while triangulation sensors provide high accuracy in smaller, confined spaces. By understanding the strengths of each technology, you can choose the best laser distance sensor for your application, whether it’s for robotics, drones, or industrial automation.

Recommended Products: